The Ackermann Story, Part 3

PA Containers and swap bodies

The third part of our Ackermann chronicle deals with the most successful years of the Ackermann company from Wuppertal. Many innovations and good sales figures characterize the company's history during the German economic miracle. Our freelancer Markus Hügle from Teningen has thoroughly researched and described in detail what Ackermann had to offer in the almost 150 years of its existence. Part 1 deals with the beginnings up to the post-war period, parts 2 and 3 describe the period up to the 1970s, and part 4 covers the last Ackermann era until the takeover by the US group Fruehauf and the bitter end in 1996.

To kick off the third part of our Ackermann chronicle, we take a brief look back at the late 1950s and show two color photographs by Detlef Gerth, which were recently made available to us. The photos show two carefully restored Ackermann panel trucks that were displayed at a commercial vehicle meeting in 2015. This is followed by a photo of a Büssing furniture truck with what Ackermann called a “steep-form cab” at the Olympic Stadium in Munich. We then turn our attention to the actual topic of this article.

After Ackermann replaced the “Type America” with its cubic successor model, it was referred to as the new “steep shape” to characterize its changed appearance. Another example of this is the photo at the beginning of this article, which shows a Mercedes 1113 belonging to the Hinz trucking company in Kassel in 1993.

An important major customer for Ackermann was the German Federal Railways. In the early 1950s, there were no standardized 20- or 40-foot containers in Europe; these did not appear until the mid-1960s. This meant that goods transported by rail had to be laboriously loaded from trucks onto wagons and then transferred back onto the road vehicles of the rail freight forwarders at the destination station in order to finally reach the respective recipient. Culemeyer road rollers could transport entire railroad cars by road to the recipient's factory for large customers who did not have their own rail connection, but there was still no satisfactory solution for smaller transport tasks.

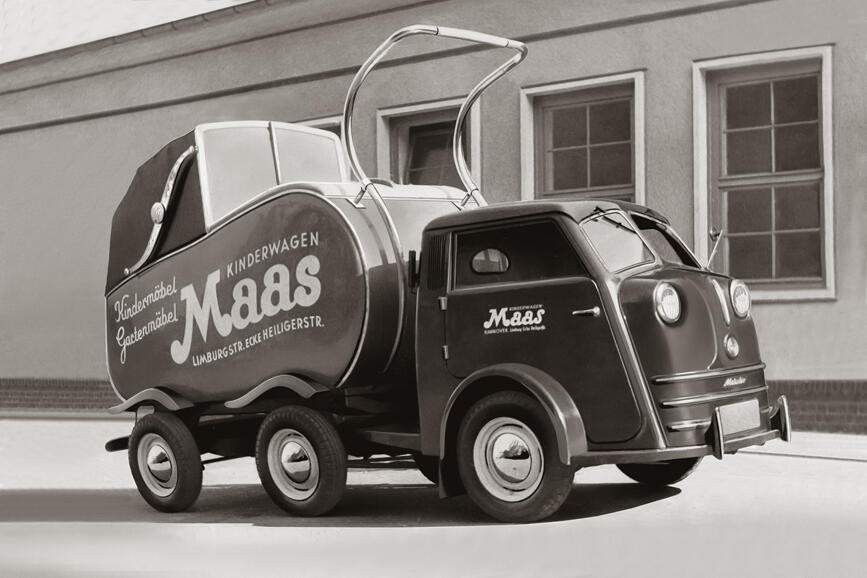

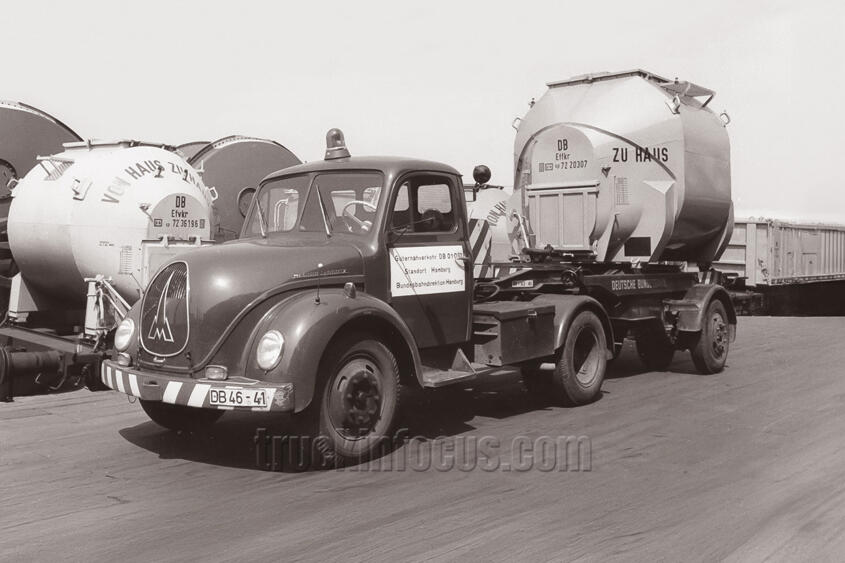

It was only with the development of the so-called PA containers that a remedy was found. PA stands for the French “porteur aménagé” and literally means “equipped carrier” or “roll container.” The German Federal Railways marketed the system under the brand name “Von Haus zu Haus” (door-to-door). The standardized containers fit on both railroad cars and trucks, but had to be rotated each time they were transferred, as they were positioned crosswise on the cars and lengthwise on the trucks.

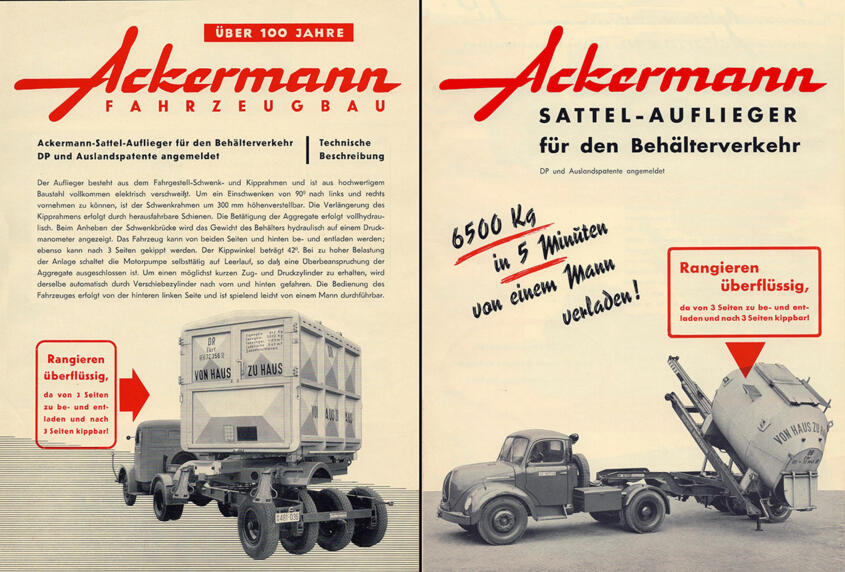

Ackermann therefore developed a special single-axle semi-trailer that could accommodate a PA container. The transfer process initially proved difficult. The simplest solution would have been to use a crane, but not every recipient company had one at its loading ramp, nor did it have the additional personnel to operate it. A crane on the trailer itself would have had a negative impact on weight and driving characteristics. So the engineers at Ackermann came up with the idea of placing a movable subframe on the trailer chassis, which would allow the driver to load a PA container from the ground or from the wagon in a one-man operation. However, space at freight yards was usually limited, and complex maneuvering cost valuable time. The subframe could therefore be rotated 90 degrees for loading and unloading from the wagon. The truck driver simply had to position his small semi-trailer parallel to the track and could then pick up the container by swiveling the subframe. Once locked in place, the journey to the recipient could begin.

The first test vehicle was built in 1950 with a Magirus S 3500 conventional truck with a square hood as the tractor unit. The S 3500 was also chosen for series production, which began in 1951, but now with a round hood. The system quickly caught on and became a great success. Depending on the load, the containers were open, closed, or round. Many breweries also opted for this combined transport.

In the 1960s, newer tractors followed, again from Magirus. The wide square-nose truck complemented its round-nose counterparts, and from 1966 there were also 135 D 11 FS cabover trucks. However, a major disadvantage was the low capacity of these containers. When the first sea containers appeared in Germany in 1966 and special semi-trailer chassis were soon designed to transport one 40-foot container or two 20-foot containers, PA containers lost their importance and finally disappeared completely in the early 1980s.

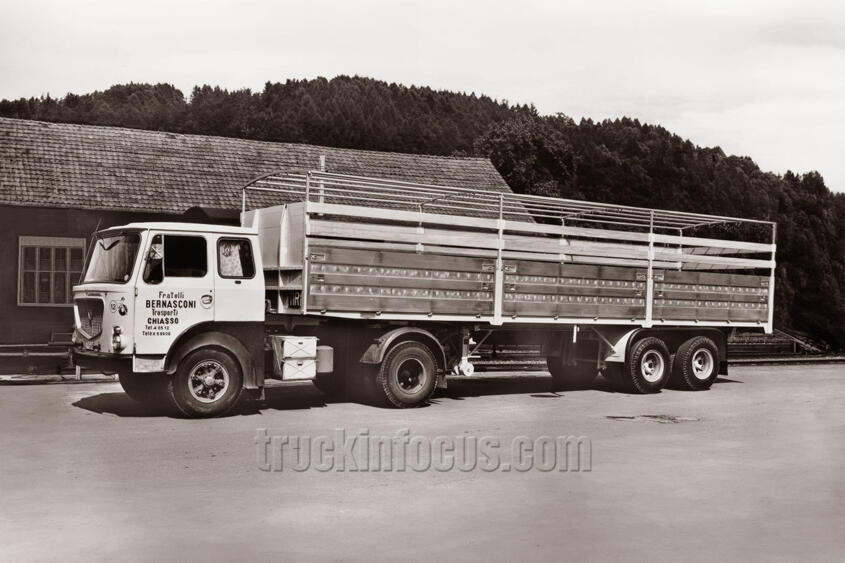

Ackermann also developed other superstructures for the German Federal Railways, such as swap bodies that could be transported on both trucks and railway wagons. Henschel cabover trucks were mostly used for this purpose.

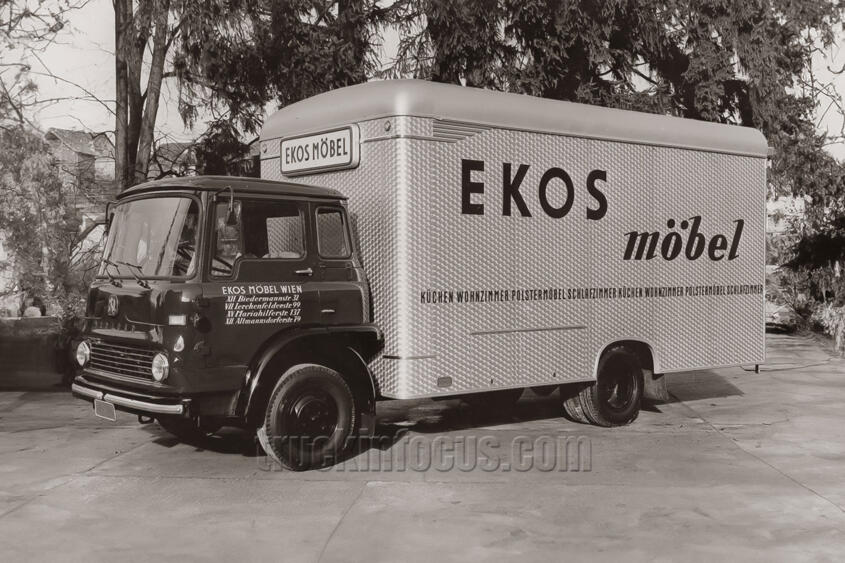

In addition, there were standard flatbed bodies for trucks and for two- and three-axle trailers of various weight classes. Like tipper bodies, they were manufactured from 1960 onwards in the newly built Plant II in Treis on the Moselle. From then on, the main plant in Wuppertal was able to concentrate entirely on closed light metal bodies. In Austria, the company Schneider & Blaha, later Brentenwerke, built light metal bodies under Ackermann license from 1957 onwards. In addition, two foreign plants were established in the early 1960s in Willisau in the Swiss canton of Lucerne and in Etreux in France, which also successfully supplied the Belgian market with bodies. In March 1964, the 10,000th light metal vehicle was delivered.

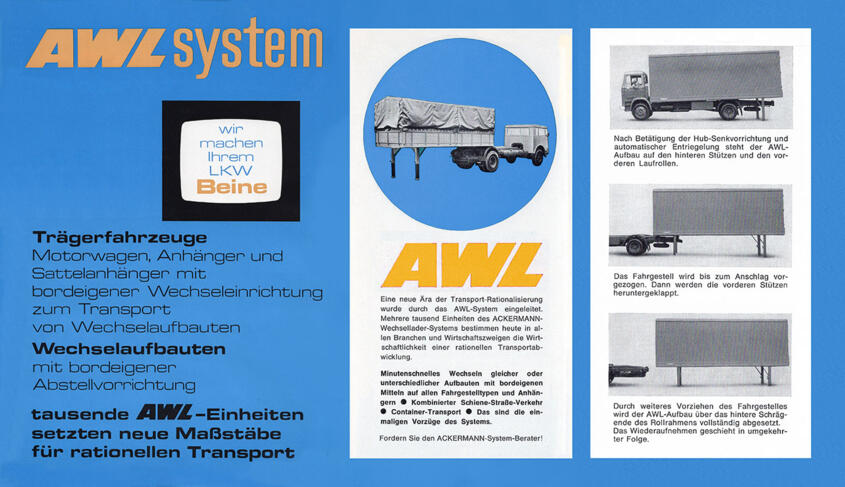

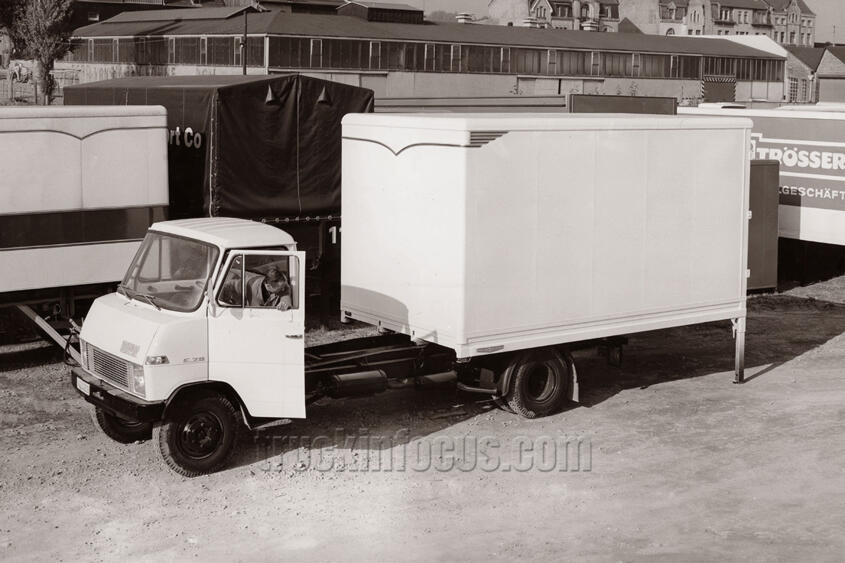

In 1965, Ackermann presented a whole series of innovations at the IAA Commercial Vehicles trade fair. Ackermann unveiled a swap body system developed in-house. The patented system, called “AWL” (Ackermann-Wechsel-Lader), enabled drivers for the first time to detach the body from the carrier vehicle independently and load a different one. Until then, almost all truck-trailer combinations, i.e., motor vehicles and trailers, had permanently mounted bodies. To load or unload, the truck had to remain stationary and the driver had to wait accordingly. The interchangeable body could remain at the loading ramp while the base vehicle was on the road with a different body.

The new system saved a lot of time and was ideal for large companies that constantly had to load finished goods, so it quickly became popular in many industries. Within about six years, several thousand AWL bodies were sold. Later, other manufacturers followed suit with similar systems. Initially, the AWL system was designed only for road transport, but shortly thereafter, the bodies could also be loaded onto railroad cars, enabling combined transport. Swap bodies had to be adapted to ever-changing length and weight regulations. The seven-meter body called Eurotainer also highlighted its importance for cross-border goods transport.

Another new feature was the roll-up wall bodies for trucks and semi-trailers. Previously, closed box bodies could only be loaded through the rear doors. Side doors were available as optional extras, but this made it almost impossible to load and unload small consignments quickly with forklifts or pallet trucks. Ackermann therefore developed movable side walls mounted on rollers for closed box bodies, so that pallets could be loaded quickly and easily with forklifts approaching from the side, or individual pallets could be removed.

From the mid-1960s onwards, closed bodies made of plastic composite construction, called AVK by Ackermann, were added to the product line. A facility in Wolfhagen near Kassel was taken over specifically for the manufacture of the corresponding components. These new bodies were mainly used for food box bodies and refrigerated vehicles.

In the mid-1960s, business was booming, with more than 1,000 employees in the various plants producing flatbed, tipper, and closed bodies as well as trailers in sophisticated series production. Even car transporters were part of the product line.

Carl Wilhelm Kölker had taken over the management of the company in the meantime. He quickly and far-sightedly recognized that in an increasingly European market, price would be the decisive purchasing criterion and that only size and specialization would enable the company to survive successfully. From around 1970, he promoted the Ackermann product line as the “Europe Program,” and from then on, flatbed vehicles were called “Internorm,” light metal bodies “Alunorm,” and refrigerated bodies “Afatherm.” This was intended to convey that standardized components enabled quick and cost-effective repairs across Ackermann's extensive service network. In the early 1970s, Ackermann had over 20 sales offices and more than 50 service stations in Germany alone.

Text: Markus Hügle