The Ackermann story, part 1

Wooden slat bodies and light alloy constructions

Vehicle bodies are indispensable for the transportation industry. Vehicle manufacturers generally only offer chassis with cabs, while the necessary bodies, trailers and semi-trailers are supplied by vehicle construction companies.

Ackermann from Wuppertal has not only made a name for itself with beautifully designed panel bodies, but also with a wide range of innovative products. Markus Hügle has researched everything Ackermann has had to offer in the almost 150 years of its existence in his company history. Part 1 deals with the beginnings up to the post-war period, parts 2 and 3 describe the period up to the 1970s and part 4 the last era up to the takeover by the US company Fruehauf and the bitter end in 1996.

Wuppertal, a city in northwestern Germany, is famous for its suspension railroad over the river Wupper, which flows right through the city center. In the days of the post-war “economic miracle“, the city was a center of German commercial vehicle manufacturing, with three companies offering the full range of truck bodies. They were the Blumhardt, Ackermann and Eylert companies. The largest in this trio was Blumhardt, with an enormously high export share. Eylert was the smallest and also the first to cease operations in 1973. Ackermann was in between in terms of size and was Europe's most important specialized factory producing enclosed aluminum bodies for transporting furniture, packaging, textiles and food. The company proudly referred to itself as "The Light Metal Specialist." All three companies had established professionally managed sales departments at an early stage. With sales offices and extensive advertising material, they were represented throughout Germany and also sold their products in other countries, whereas many German body manufacturers primarily supplied their immediate region. In this way, all three companies succeeded in establishing their names as memorable brands in commercial vehicle manufacturing.

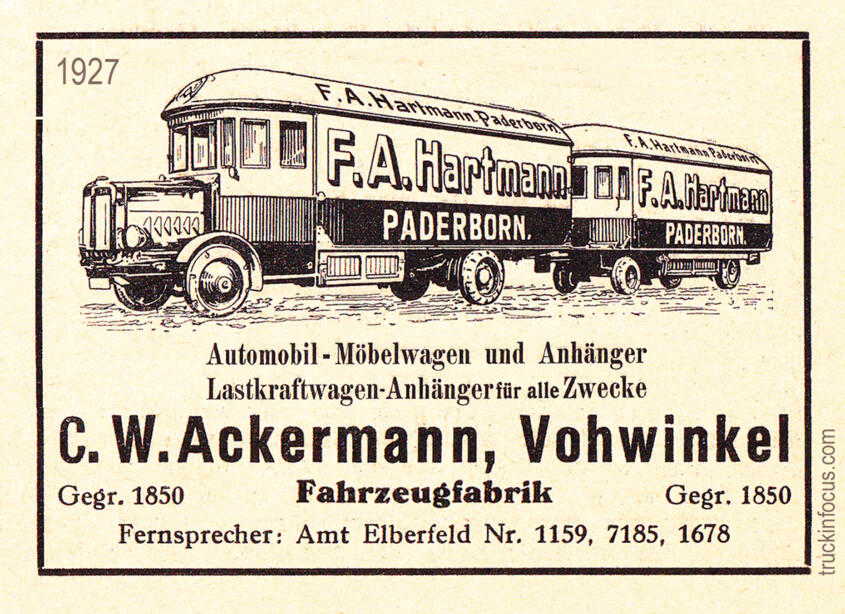

But let's start at the beginning: In 1850, vehicle builder Carl Wilhelm Ackermann founded a wagon construction workshop in Vohwinkel. The city of Wuppertal did not exist at that time; it only came into being in 1929 through the merger of the two cities of Elberfeld and Barmen and other towns such as Cronenburg, Roßdorf and Vohwinkel. Cronenburg was home to the Clerck company, a specialist in chassis conversions that later also supplied Ackermann. At first, all kinds of trolleys were built, focused on agriculture and, of course, horse-drawn carriages.

Soon, however, the company specialized in commercial vehicles, whose customers were mainly in industry. Heavy, horse-drawn flatbed trucks and plateau low-loaders for transporting bulk materials, building materials and machinery were part of the product range around 1900. As more and more motorized tractors came into use from around 1910, Ackermann offered the matching trailers.

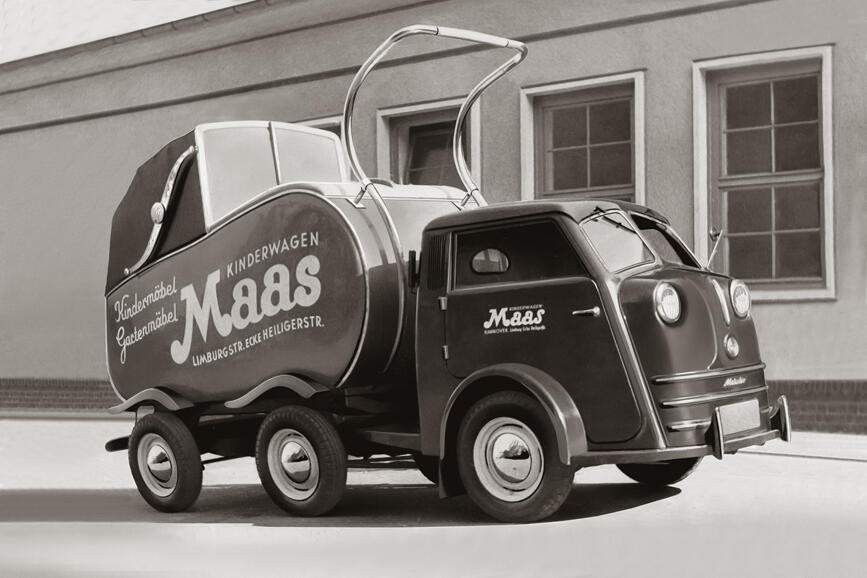

A little later, the first enclosed special bodies for the then newly emerging trucks were also built. Furniture vans and smaller bodies for food transport were a particularly important area.

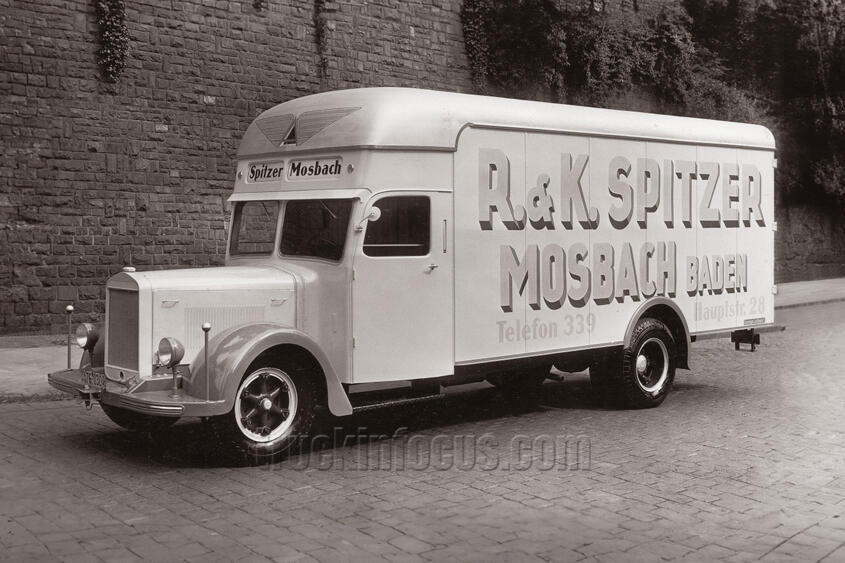

At that time, enclosed superstructures were built using the wooden slat construction method. A wooden subframe was mounted on the iron vehicle frame to support the body. This consisted of a wooden frame to which vertical wooden slats were affixed. The roofs were usually semi-circular in shape, which was common on railroad cars at the time.

The major disadvantage of this construction method was the heavy weight of the superstructure. This not only reduced the payload, but also placed enormous strain on brakes, tires and running gear of trucks and trailers in often adverse road conditions. At first, attempts were made to remedy the situation with larger engines and reinforced chassis, but this only made the vehicles heavier. The solution could therefore only lie in an alternative material, the magic term being "light metal" instead of wood.

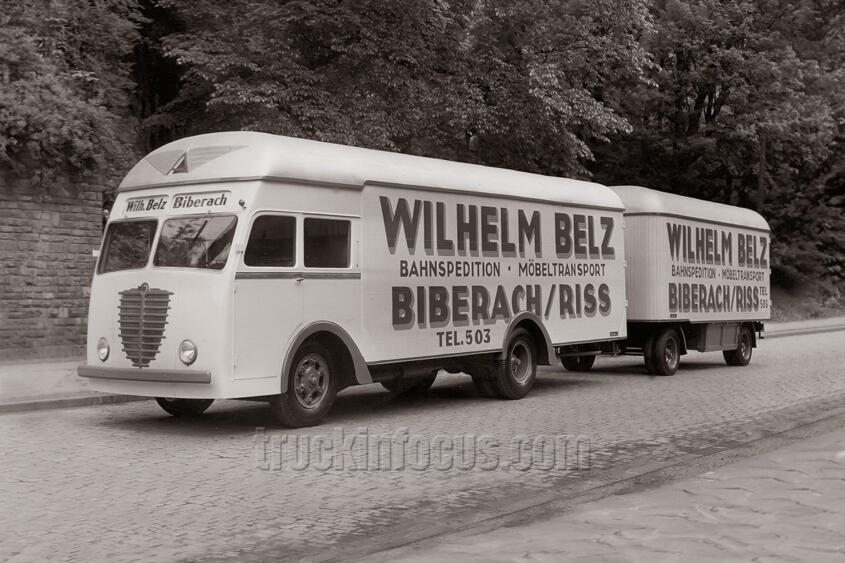

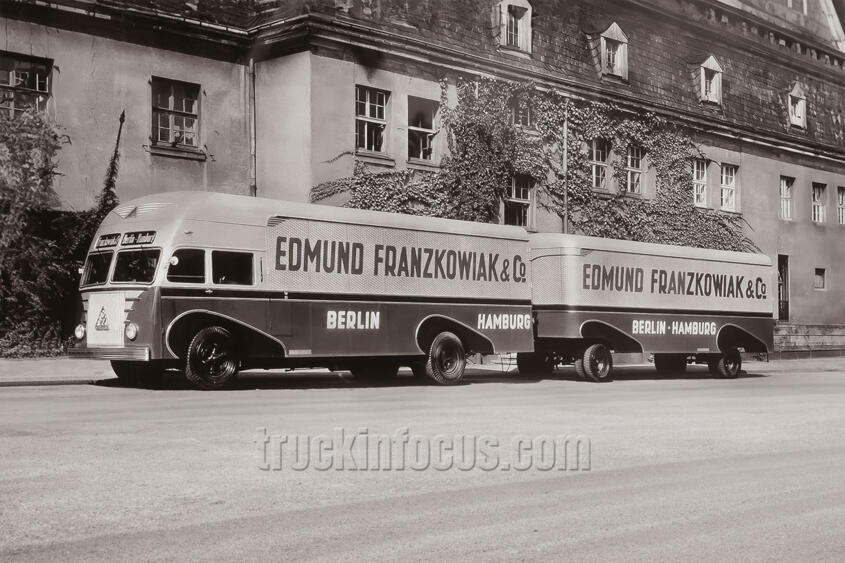

In the 1930s, Ackermann had gained a good reputation among furniture forwarders, and stately furniture trucks with matching trailers on truck chassis from various manufacturers left the factory halls. Along with the Schumann company in Werdau, Ackermann was the leading supplier of wooden furniture carts, which were traditionally large and elaborately lettered.

The vehicles were the business card of every haulage contractor, and the demands on the lettering painters, who knew their trade very well, were correspondingly high. At the same time, the engineers and designers at Ackermann were eagerly experimenting with the new material of light metal. Other body manufacturers, such as Staufen Fahrzeugwerke in Eislingen, also made their first experiments with aluminum alloys. But the outbreak of the Second World War put an abrupt end to these efforts. Like all other companies, Ackermann was integrated into the war economy and produced now mainly standard trucks suitable for military use.

In 1943, large parts of the Ackermann plant were destroyed by Allied air raids, as were many other industrial plants in Germany. It was not until after the currency reform in 1948 that experiments with light metal designs resumed under the then-owner Karl Kölker, later supported by his son Carl Wilhelm Kölker.

Ackermann's concept envisaged a frameless panel structure. The panels were solidly connected to each other by clamping profiles developed in-house and formed a load-bearing structure. Rivets and screws could be dispensed with and a smooth outer surface achieved.

The vertical light metal panels represented a well thought-out modular system that could be easily adapted to different wheelbases of the carrier vehicle and was also variable in height. In the event of damage, individual light metal elements could be replaced quickly and cost-effectively. Ackermann had this design patented. Its competitor Staufen also had a patent for light alloy bodies, but its concept differed from the Ackermann principle in that it used riveted joints.

Light metal superstructures soon became established. Although some movers were still skeptical at first and continued to order wooden slat bodies, by the early 1950s at the latest, only light metal was used because customers were now finally convinced. The need for new vehicles was great at that time, because the makeshift repaired or elaborately rebuilt pre-war vehicles and the old, heavy trailers had had their day.

If you liked this article, simply click here to go to the second part of the Ackermann story.