The Ackermann Story, Part 2

Furniture trucks with wings

Bodies for trucks, trailers and semi-trailers are essential in the transport industry. Body construction companies are responsible for providing them, ensuring that commercial vehicles are fit for purpose. This is because vehicle manufacturers usually only supply chassis with cabs.

This article is about the body manufacturer Ackermann. Our freelancer Markus Hügle has researched the history of the Wuppertal-based company for us and described in detail what the company has had to offer in the almost 150 years of its existence. Part 1 deals with the company's beginnings and its development in the post-war period, while parts 2 and 3 describe the period up to the 1970s. Part 4 covers the final era in Ackermann's history, up to its bitter end in 1996.

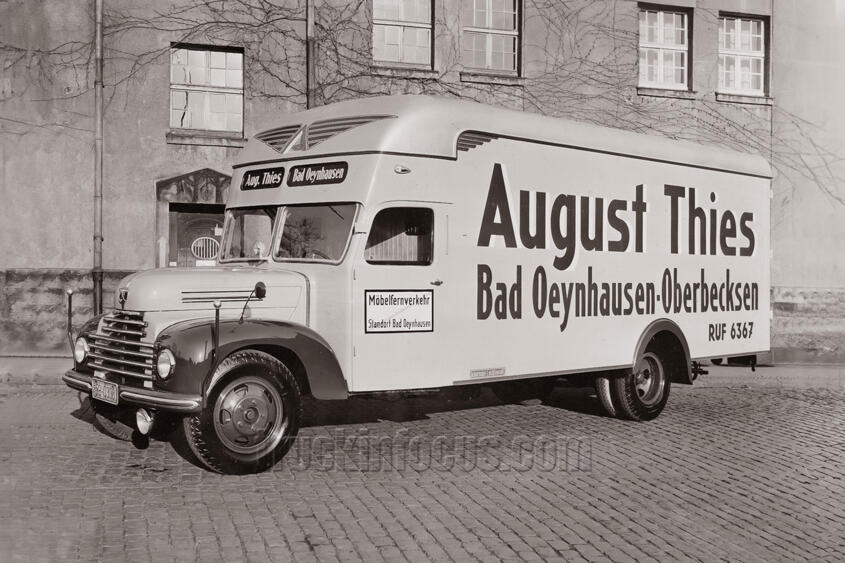

In the period after the Second World War, vehicles with long hoods were the standard design for trucks. In the Federal Republic of Germany, Magirus initially offered its medium-heavy S 3500 model with a square hood, and from 1951 with an elegant rounded hood. Mercedes-Benz presented the completely new L 3500 in 1950, and MAN had the MK series in its range, while Henschel presented its successful HS 100 model in 1951. The chassis of these trucks in particular were used as the basis for furniture van bodies, with bus chassis also being used, as these were particularly suitable due to their low loading sill. In particular, Mercedes-Benz and Magirus supplied their bus chassis, designated O 3500, to Ackermann at the request of customers.

Ackermann boss Kölker knew that a catchy brand name, effective advertising and a good reputation could bring visible sales success. So he had almost all new vehicles professionally photographed before delivery and printed brochures confidently touting the benefits of his products. He also gradually and successfully built up a well-functioning sales and service network in order to be close to the customer. At that time, Ackermann was already the market leader in Germany for furniture truck bodies. The main competitors were Staufen in Eislingen, Kässbohrer in Ulm, Buschbaum in Hanover- Langenhagen and, in the immediate vicinity, the Eylert company in Wuppertal-Sonnborn.

The fact that the hood of the trucks reduced the loading length was a problem that all German hauliers were aware of. The solution came from above, so to speak. The "Seebohm Laws" of 1958, named after the then Minister of Transport Hans-Christoph Seebohm, provided for drastic length and weight restrictions for trucks in the Federal Republic of Germany in order to give the German Federal Railways, i.e. rail transport, an advantage over road haulage. The desired success failed to materialize, but the measure did promote the development of the cab-over. The engine mounted over the axle at the front restricted the space in the cab, but increased the loading length significantly.

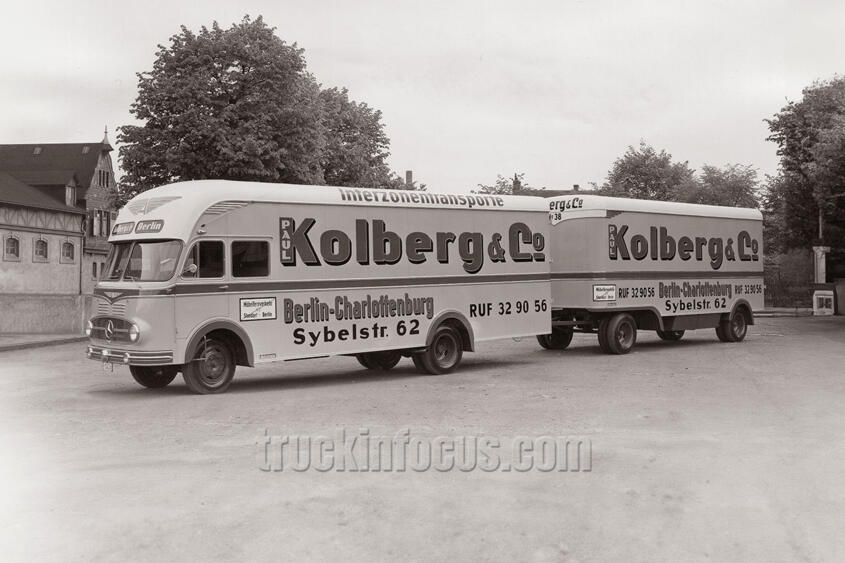

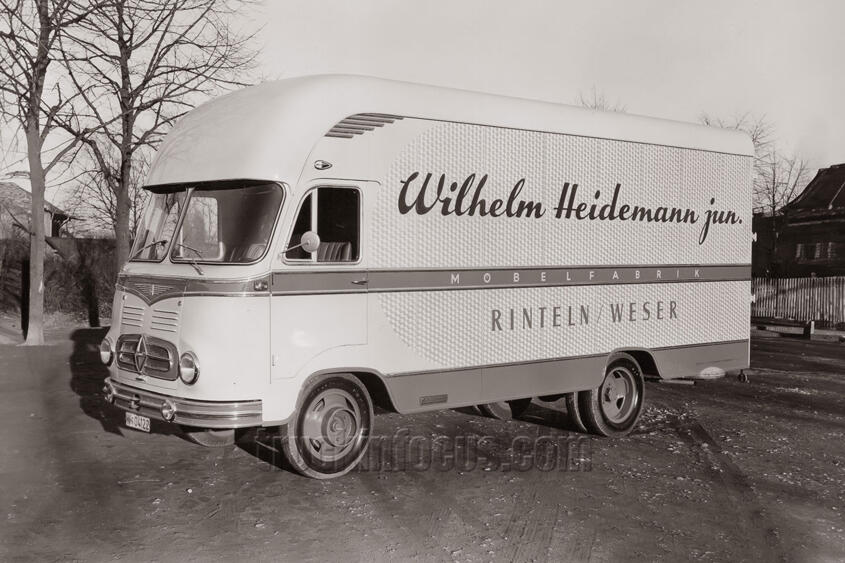

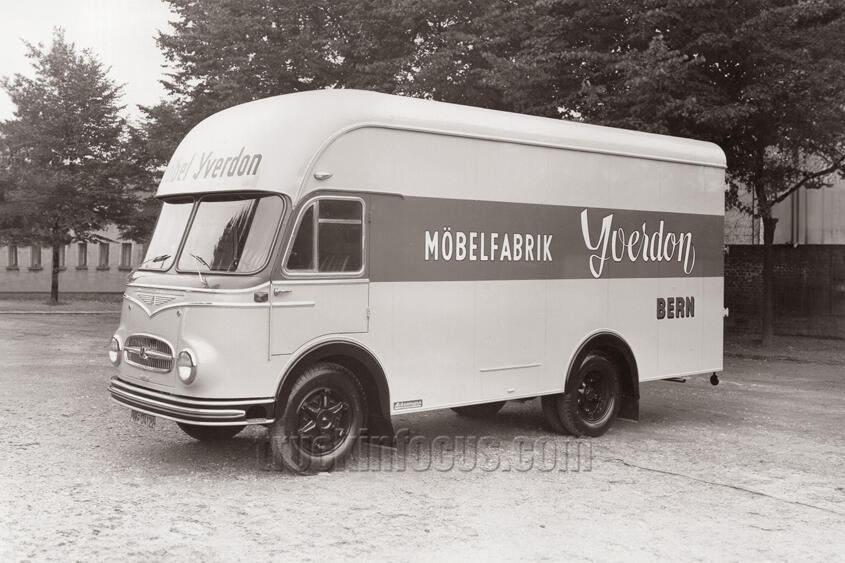

Büssing was the only German truck manufacturer to use the underfloor engine. Located between the axles, it banished noise and the smell of diesel from the cab. Büssing also supplied underfloor and bus chassis for furniture bodies. For all other manufacturers, the chassis of the conventional trucks had to be converted to cab-overs. This was done, for example, by the specialist Clerck. It was not until the mid-1950s that Mercedes-Benz had its own cab-over chassis, with MAN and Magirus following shortly thereafter. By this time, Ackermann had already developed an attractive design for its cab-over furniture trucks. The integrated driver's cab and the box body formed a harmonious unit. Under the front roof dome there was space for packing material and optionally there was a second row of seats for the moving personnel, recognizable by the additional side window. Moving customers could also be seated here, as not everyone had their own car at that time.

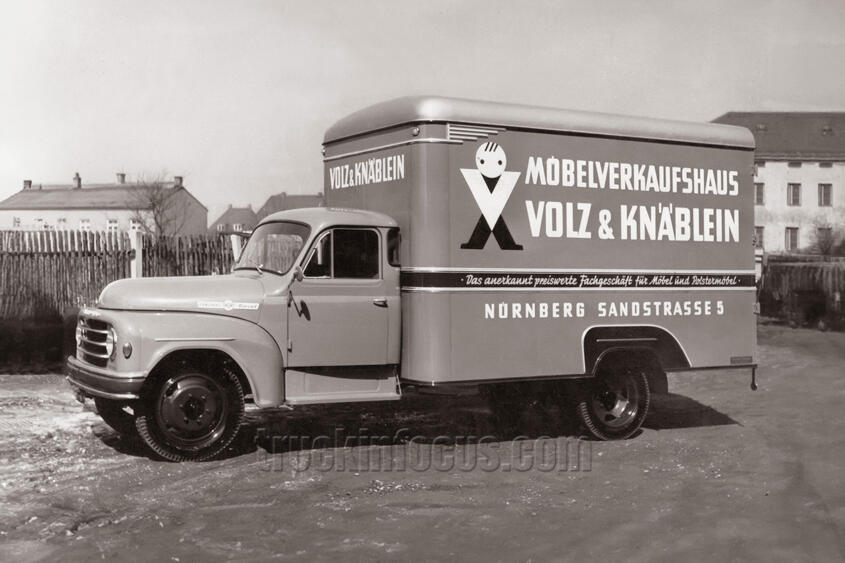

The design of the front panels was initially not the same for every vehicle. The hand-finished sheet metal parts varied from vehicle to vehicle. The differences were apparent in the arrangement of headlights and trim strips as well as the emblems of the respective chassis manufacturers. The shape of the windshields was also not uniform; there were differences depending on the supplier of the windshields. In 1957, however, Ackermann moved to a uniform design for all cab-over furniture trucks and used front panels from large-scale production, which were manufactured with press tools and consisted of three parts. The center part could be adapted to the respective vehicle width. The parts at the vehicle corners were laterally variable to accommodate different overhang lengths. In addition, the openings for the headlights had to be cut out individually. The windshields now always had the same shape, because they too came from series production. The new cab-over trucks were given the internal designation "Type Amerika", but also became known as Pullman furniture trucks.

Typical of Ackermann box trucks and trailers were the stylized wings made of trim at the top of the sides of the bodies. Above the windshield, the trucks bore a painted "A" with wings, unless the customer insisted on his own lettering. The connoisseur could therefore immediately recognize Ackermann furniture trucks. In addition, the name was attached to the lower edge of the side of the body on a small embossed sign. The box trucks were built in this form for almost ten years and Ackermann achieved a market share of around 70 percent with them. Minor changes were made to the steps, which from around 1960 onwards were solid instead of the usual step bars.

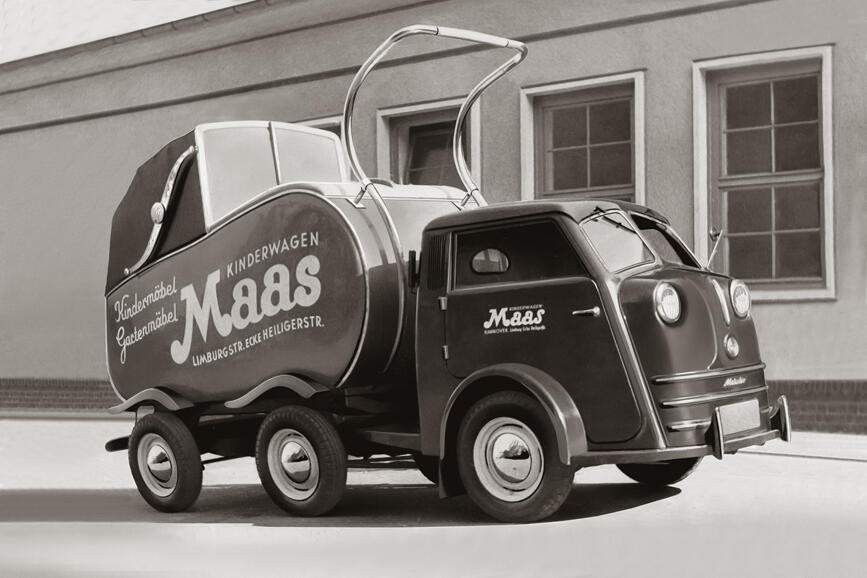

In addition to the large "Pullmans," as they were often called, there were also box bodies in light-alloy construction on medium-weight and light chassis. These also featured the "Ackermann wings" and the embossed side sign in the same style. As early as the 1950s, Ackermann was no longer able to meet demand, so licenses were granted to a number of smaller bodybuilders throughout Germany. In Berlin, for example, the Wingert company took over this task. Primarily light metal box bodies on smaller commercial vehicles such as the Hanomag L 28, the Opel Blitz or, until 1961, on Borgward and Ford chassis were produced by these companies, which mostly supplied customers in their respective regions. In 1955, Mercedes-Benz also entered this market segment with the extremely successful type L 319. Trucks in the one-and-a-half to three-ton weight class were used primarily to deliver new furniture from the numerous family-run furniture stores at the time to end customers, as well as to transport food. In Austria, the company Schneider & Blaha, later Brentenwerke, began building light-alloy bodies to Ackermann specifications under license in 1957 and developed into a successful supplier.

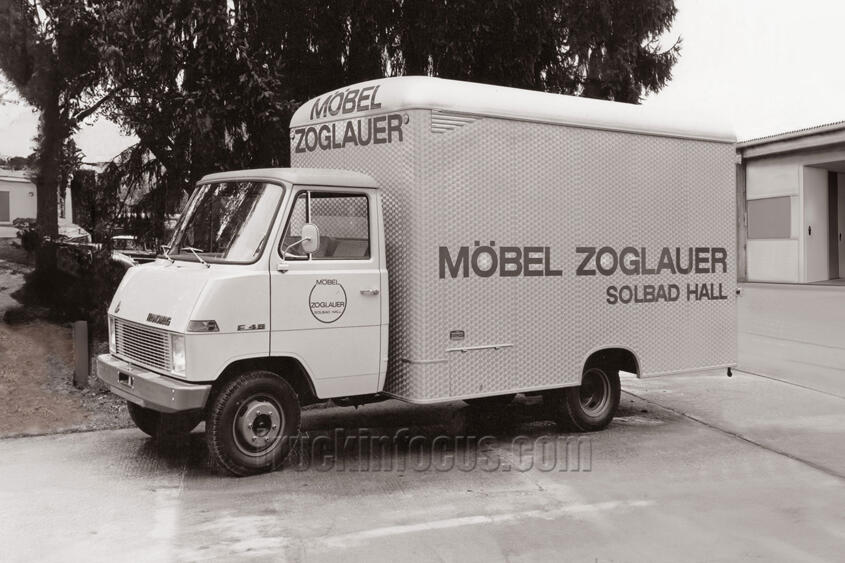

From the mid-1960s, angular shapes became generally accepted in vehicle construction. Furniture vans with rounded fronts were beginning to look outdated. Therefore, in 1966, Ackermann presented a "new face" with a vertical front and large windows without a center bar. The area above the windshield was now also almost vertical, and the cars thus offered even more storage space above the driver's cab. With the new Ackermann front, bodies were delivered on Büssing FSA chassis (the initials FSA stand for chassis for custom bodies), and to a much lesser extent also on MAN chassis.

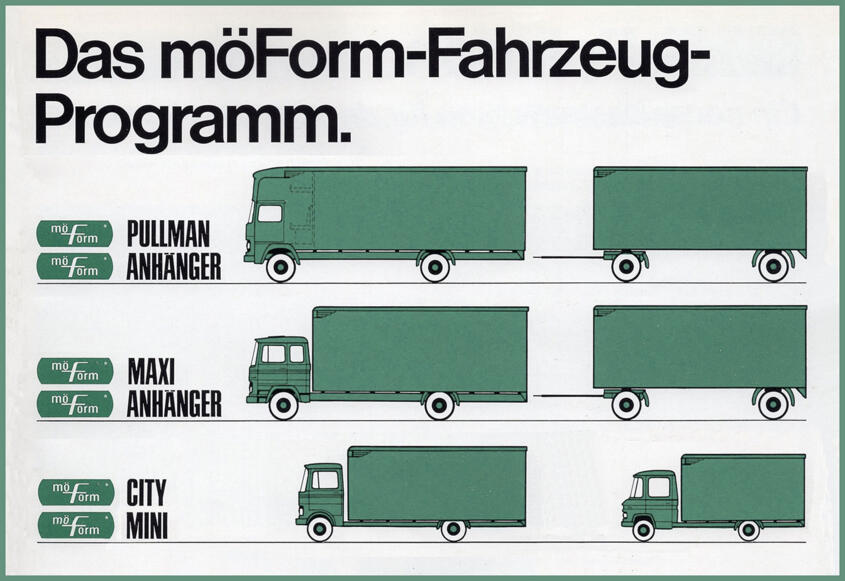

The vast majority of second- generation "Pullmans" were built on Mercedes-Benz chassis, primarily of the LP 1113 type, with almost all buyers preferring the Mercedes-Benz factory front, which visually corresponded to the cubic LP 1620 already introduced in 1963. Ackermann's large panel vans were still available in this angular design until about the mid-1970s. From the end of the 1960s, they were marketed under the name "Möform" as part of an overall concept developed in cooperation with Deutsche Möbeltransport GmbH (DMG). In addition to the vehicles, it also included packing materials, work clothing and staff training. The close cooperation with Mercedes-Benz and the low maintenance costs due to standardized construction and parts were emphasized. The large box and box-type vans were given the designation "Maxi", the smaller box vans on MB-LP-608/808 chassis were called "City" (mainly for inner-city traffic) and the small vans on MB-L-406/508 basis were called "Mini". They were mainly used to deliver new furniture to private customers.

Increasing cost pressure in the transport industry as well as the emergence of interchangeable bodies made the "Pullmans" unattractive, as they were significantly more expensive than box trucks with factory-fitted cabs. In addition, at the beginning of the 1970s, the maintenance-friendly tipper cab became established in truck construction, for which the integrated design of cab and cargo area in the box truck was unsuitable. Only the Warneke company in Laatzen near Hanover developed a Pullman furniture truck with tipper cab on the then new Mercedes-Benz NG in 1977 for which it held a patent. Until Warneke ceased production in 1997, these vehicles were built in small numbers, but were rather exotic in the furniture van sector.

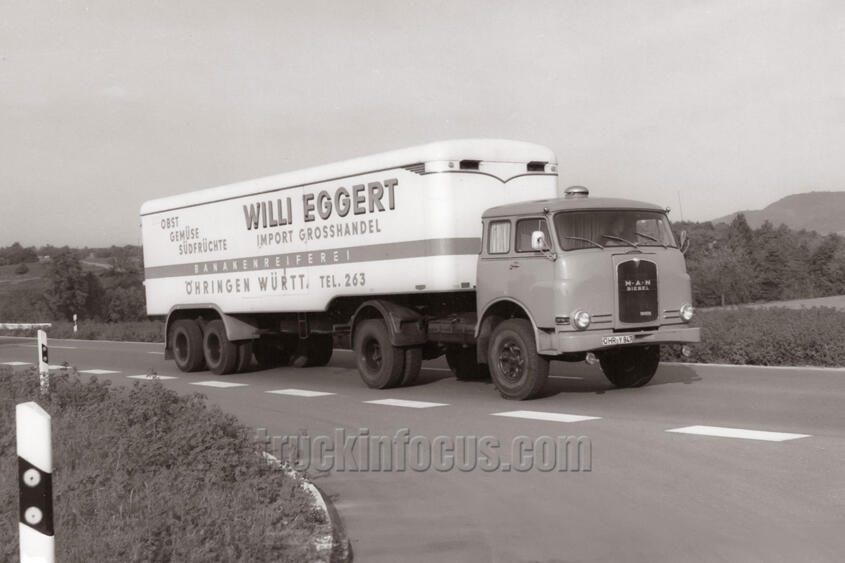

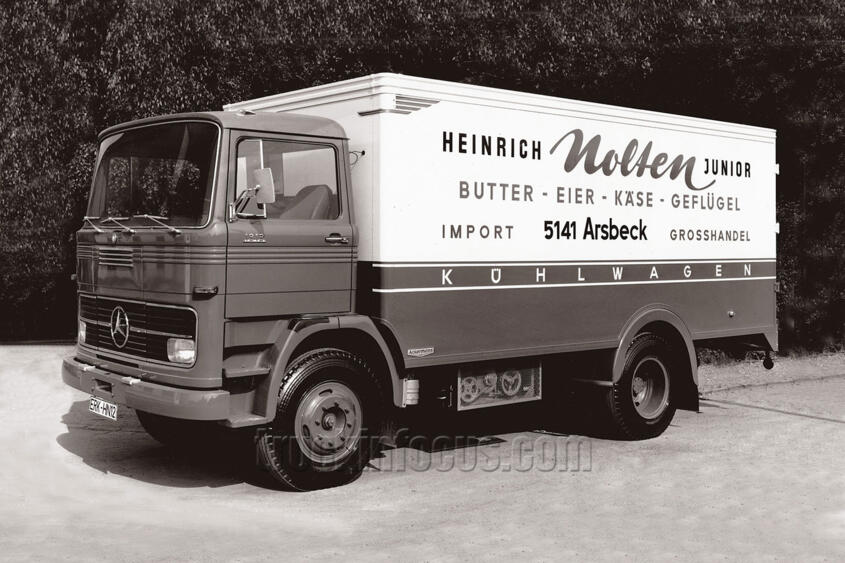

In addition to furniture trucks, refrigerated trucks were an important production area at Ackermann. For foodstuffs such as bread, milk and cheese, which were usually only transported over short distances, small box bodies made of aluminum alloys were sufficient. Here too, in addition to the light trucks from Hanomag, Opel and Borgward, the Mercedes-Benz L 3500/311 and the S 3500/4500 from Magirus, the short trucks from Mercedes-Benz and MAN were later widely used in the medium weight class. For long-distance transport, especially for meat transport, the simple side walls were not sufficient to keep the perishable goods fresh. Initially, additional insulation and dry ice bars were used, but from the end of the 1950s, separate refrigeration units were the solution. They were mounted on the front of the body, later also underfloor on the chassis, and equipped with their own drive for constant cooling. The requirements for this were closely coordinated with the "Transfrigoroute", the association of refrigerated hauliers. Karl Kölker was instrumental in the development of the corresponding refrigeration technology and Ackermann, along with several other body manufacturers, established itself extremely successfully in this market segment in the 1960s, due in part to the steadily increasing demand resulting from the growing cross-border traffic in Europe.

If you liked this article, simply click here to go to the first part of the Ackermann story.