The Borgward chronicle with Hansa-Lloyd from 1931, Goliath, and Lloyd

Page 1

By Christoph Büch and Steve St.Schmidt (2026)

The Borgward chronicle on truckinfocus.com contains ten pages with more than 180 images. You can view everything page by page or go directly to the topic of your choice — just click on a page title. We wish you good entertainment!

Page 01 – Borgward in the 1920s

Page 02 – Goliath in the 1930s

Page 03 – Hansa-Lloyd in the 1930s

Page 04 – Borgward in World War II

Page 05 – Borgward after 1945

Page 06 – Goliath in the 1950s

Page 07 – Lloyd in the 1950s

Page 08 – Borgward in the early 1950s

Page 09 – Borgward in the late 1950s

Page 10 – Heyday and decline

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

Borgward in the 1920s

Carl Friedrich Wilhelm Borgward was born on November 10, 1890, in Hamburg-Altona, the son of a coal merchant. At the age of 16, he completed an apprenticeship as a locksmith and went on to train as an engineer. The First World War interrupted his career and he was seriously wounded as a soldier on the Western Front. After a long stay in a military hospital, he had to be discharged from military service at the end of 1915. When the war ended in November 1918 with Germany's surrender, he found employment as an engineer with the Bremen-based company Carl Francke, which manufactured textile machinery, among other things. Borgward proved himself and soon became chief engineer.

In 1919, businessman Ernst Baerold was looking for a partner for his small Bremen-based company, Bremer Reifendienst GmbH (Tire Service Bremen Ltd), and found him in Carl F. W. Borgward. The company's product range was soon changed, and it concentrated on the manufacture of car radiators and fenders. The renowned Bremen-based automobile manufacturer Hansa-Lloyd was the most important customer.

In 1921, Baerold gave up his shares in the company and Borgward, at the age of 30, became the sole owner of the company, now operating under the name “Bremer Kühlerfabrik Borgward und Co.” At that time, the company employed 60 people.

Borgward had long wanted to produce a car, but had to admit that neither the premises nor the financial resources were sufficient for this. In order to get closer to his goal and at the same time solve the transport problems on his own company premises, in 1924 he teamed up with his master craftsman and designer Dietrich Klie to develop a small three-wheeled transport vehicle powered by a 2.2 hp single-cylinder two-stroke engine from DKW, which was located in front of the left rear wheel. The driver sat behind the rear axle on a saddle and steered the front wheel using a motorcycle handlebar connected to cable pulls. There was no gearbox or starter motor; the vehicle had to be pushed to start the engine. Borgward christened the vehicle the “Blitz” motor cart. Later, the name Blitzkarren became more widely used. Borgward also offered the vehicle for sale to other commercial enterprises. With a payload of a quarter ton and a price of only 980 marks, it promptly filled a gap in the market. In the same year, over 100 of these tax- and license-free cargo motorcycles were sold.

In 1925, Wilhelm Tecklenborg, son of a well-known shipowner and shipyard owner, recognized the potential of small transporter production, joined Borgward as a partner, and took over the commercial management. Carl F. W. Borgward himself was now able to concentrate fully on vehicle design.

The successor model to the Blitzkarren from 1926 had double the payload and was powered by a 6.5 hp ILO engine. Borgward soon sold 500 Blitzkarren and granted licenses for the construction of the vehicle to three other companies in the Bremen area. In fact, total sales of the Blitzkarren rose to 10,000 vehicles in 1927. Some were sold under the name “Goliath” and, on request, were also offered with a starter motor.

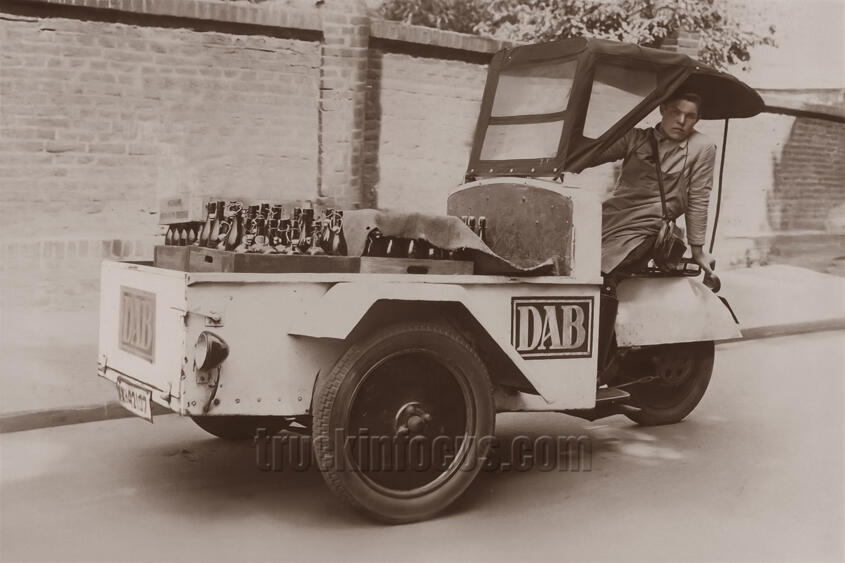

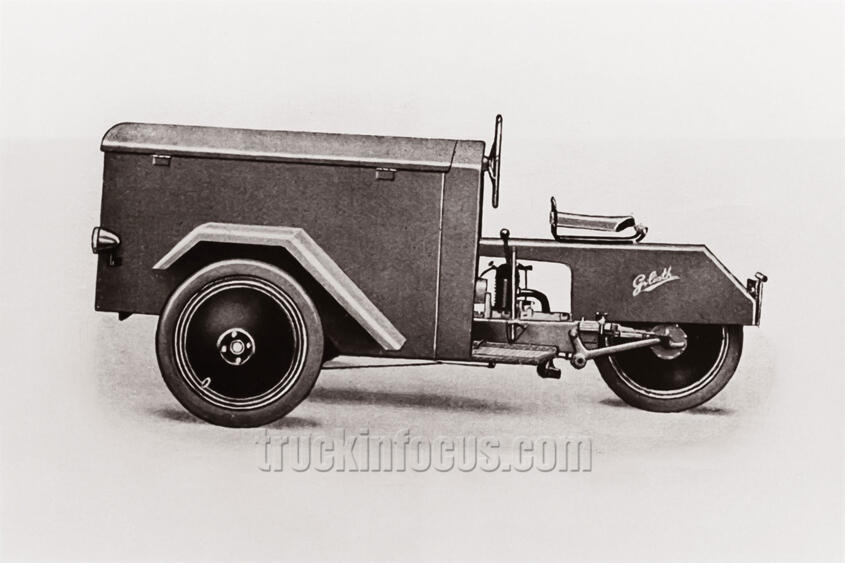

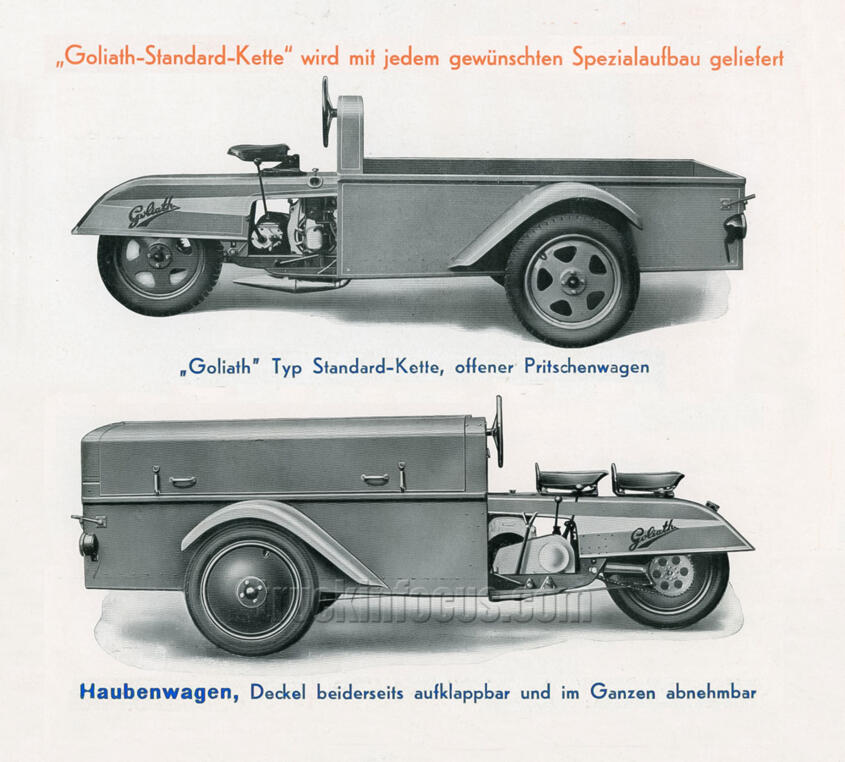

The success of the Blitzkarren led to further development in 1926 in the form of another three-wheeled vehicle, which was initially offered under the name “Goliath small delivery van”. There were “open wagon,” “conventional truck,” and “closed wagon” versions. In all three variants, the driver sat behind the loading area in the open air and steered the vehicle using a vertical steering wheel. The sensitive cable pulls were replaced by linkages and the driving force was transmitted by roller chains. The equipment included a starter, clutch, three-wheel brake and, optionally, two headlights and an electric horn. There were also two-seaters, in which a passenger could sit behind the driver on a second saddle.

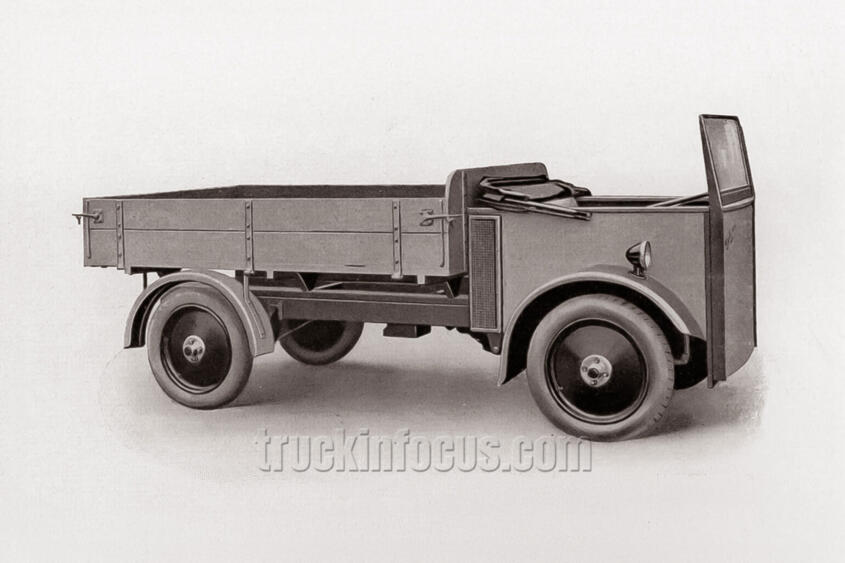

In 1927, the first four-wheeled vehicle came onto the market and was initially called the “four-wheel rear loader.” In 1929, the small cabover with a payload of 0.65 tons was christened the “Goliath Express.” Under the slogan “The perfect small truck,” the chassis was available for 2,250 marks, and depending on the body (primed), the price rose to up to 2,500 marks. A panel van including paintwork cost 2,590 marks. The cab with windshield and folding top offered space for two people and was located in front of the loading area. Access was via a door at the front of the vehicle, whose air-cooled engine produced 14 hp. Features included cardan drive, bevel gear differential, four-wheel brakes, and speedometer. The maximum speed was 45 kilometers per hour.

In 1929, the cargo motorcycles, which had previously been referred to as small delivery vans, were renamed. For 1,850 marks, the “Standard” model was now available, powered by a 7.5 hp single-cylinder engine with “turbo cooling.” The maximum speed was 40 kilometers per hour. The vehicle had three gears plus reverse, cardan drive, and rear suspension. The payload was half a ton. The Goliath Standard became a symbol of new mobility for tradespeople and small retailers. According to a law passed in 1928, motor vehicles with fewer than four wheels and an engine capacity of less than 200 cubic centimeters could be driven without a driver's license. They were also tax-free. This was another reason why a corresponding model called the “Rapid” remained on the market. The open flatbed version cost 1,150 marks, while the panel van cost 1,225 marks. Lighting was available as an option, the payload was a quarter ton, and the vehicle was powered by a 3.5 hp engine that enabled a top speed of 35 kilometers per hour.

The rising sales figures soon led to a considerable increase in the workforce to around 300 employees. The company was owned in equal parts by Carl Borgward and Wilhelm Tecklenborg and operated under the name “Goliath Werke GmbH Borgward & Tecklenborg” until 1937. The small delivery vehicles from the Bremen-based manufacturer were unrivalled in terms of low operating costs at the time, so that soon every fourth commercial vehicle in Germany was a Goliath. In 1928, the company acquired another production facility in Bremen. This was the former bodywork factory of Louis Gaertner AG on Föhrenstraße, on the corner of Osterdeich. The site was directly opposite the administration building of the established vehicle manufacturer Hansa-Lloyd, which had sourced its bodywork from there until 1927.

By 1929, Borgward already had foreign representatives in Argentina, Denmark, England, the Netherlands, Austria, the Saar region, Switzerland, Czechoslovakia, and Hungary.

The economic crisis of 1929 had only a minor impact on Borgward as a manufacturer of inexpensive vehicles, but it hit the vehicle manufacturer Hansa-Lloyd with full force. This enabled Borgward to acquire a majority stake in Hansa-Lloyd at a low price and, in 1931, even the entire company, which he subsequently restructured extensively. He discontinued production of Hansa's luxury cars, as these had contributed significantly to the company's financial decline. He also reduced the workforce from 2,000 to 750 employees. The well-known Hansa-Lloyd brand name was retained for the commercial vehicle models, which continued to be produced successfully. Production of the Hansa-Lloyd electric trucks also continued. The company name was changed to “Hansa-Lloyd und Goliath Werke, Borgward & Tecklenborg oHG.”