The Borgward chronicle with Hansa-Lloyd from 1931, Goliath, and Lloyd

Page 4

By Christoph Büch and Steve St.Schmidt (2026)

Borgward in World War II

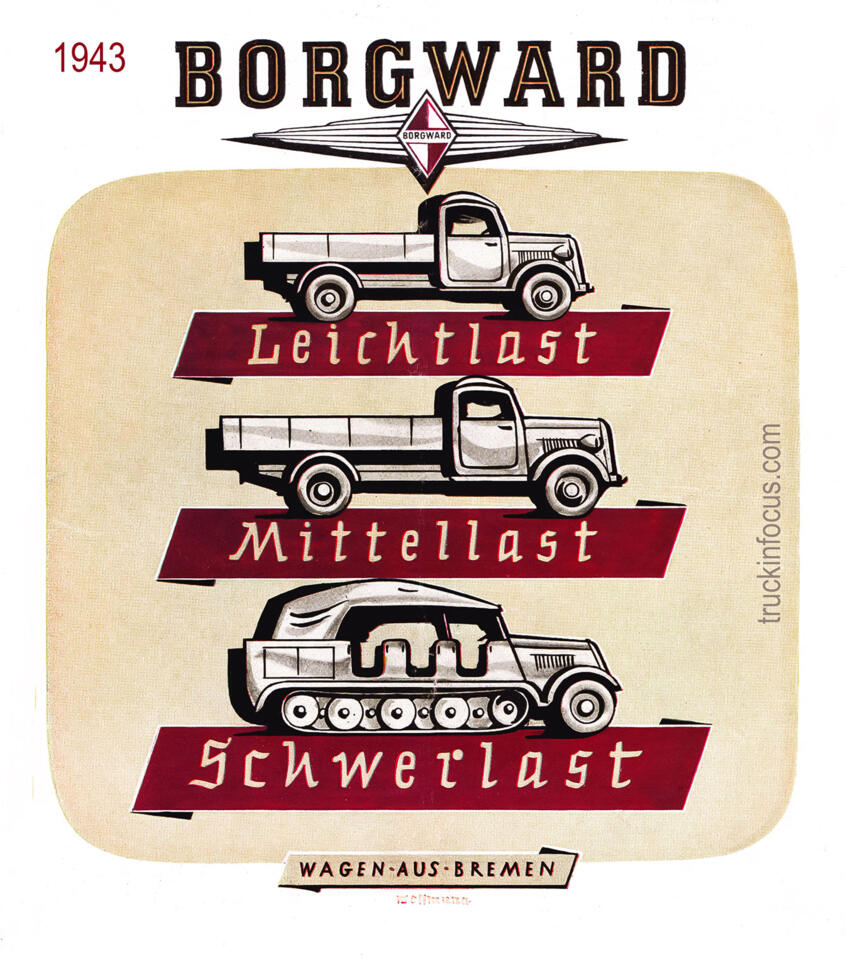

On September 23, 1938, Borgward inaugurated its new plant in Bremen-Sebaldsbrück. From that day on, the company operated under the name Carl F.W. Borgward, and the name Hansa-Lloyd was finally history. In the course of increased rearmament, the Nazi government regulated the production of all German vehicle manufacturers. Borgward was instructed to limit itself to the production of trucks with payloads of one to three tons.

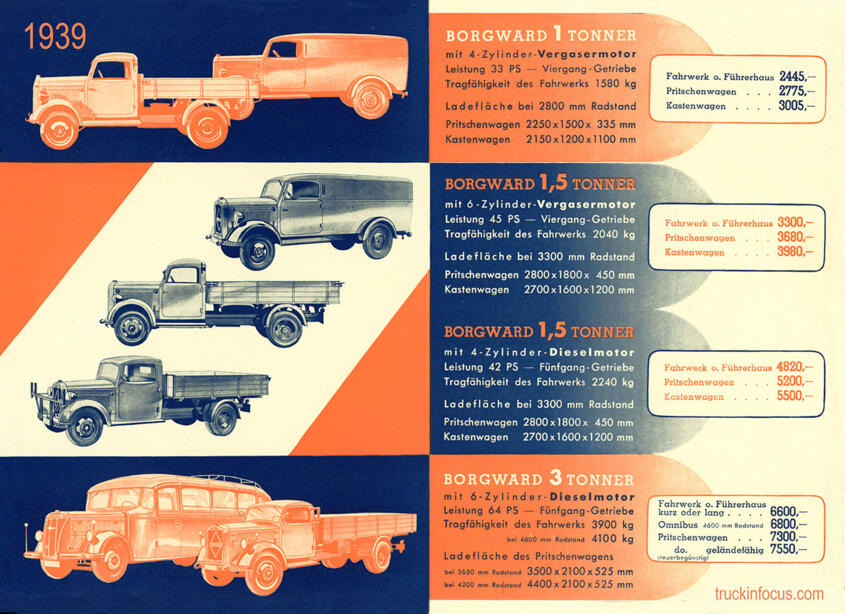

In the one-ton payload range, Borgward produced the B 1000 model with a 1.4-liter gasoline engine and 33 hp. The vehicle was initially built from 1938 to 1943. From 1937 to 1939, the L 2000 S model was added as a one-and-a-half-ton truck with a 47 hp gasoline engine and two liters of displacement. In 1939, it was upgraded to the L 2300 with 55 hp and 2.3 liters of displacement and rolled off the production line until 1942. The three-ton “Borgward 3 t” was built from 1938 with a six-cylinder gasoline engine (Borgward B 3000 S/O) and from 1939 with a diesel engine (Borgward B 3000 S/D). After production of all Hansa-Lloyd trucks was discontinued, the Borgward three-ton truck was the heaviest truck produced in Bremen. From 1939, at the request of the Reich Ministry of Transport, there was also a version with an Imbert wood gas generator. From 1940, the doors were hinged at the front. Production of the gasoline version ended in 1942, while the diesel version continued to be built until 1943. From 1942 to October 1944, Borgward also produced an all-wheel-drive version of the three-ton truck with the type designation B 3000 A at its Sebaldsbrück plant until the factory facilities were destroyed by Allied bombers.

Borgward realized an innovative defense technology project with the Mine Clearer IV (Minenräumer IV). Built from 1942 onwards, this conditionally remote-controlled, tracked explosive carrier was a novelty, even though similar inventions had already been tested in France. The vehicle was equipped with state-of-the-art radio remote control and could detonate explosive charges in a controlled manner. As soon as the small tank reached the target area, the driver got out and withdrew. This was the most dangerous part of the operation for him, as he was now almost completely exposed to enemy fire. The vehicle was then driven to its destination by radio. There, the explosive charge was detonated remotely and the vehicle was steered out of the danger or explosion zone. With nearly a thousand units manufactured, the Minenräumer IV was a significant milestone in the field of military robotics at the time.

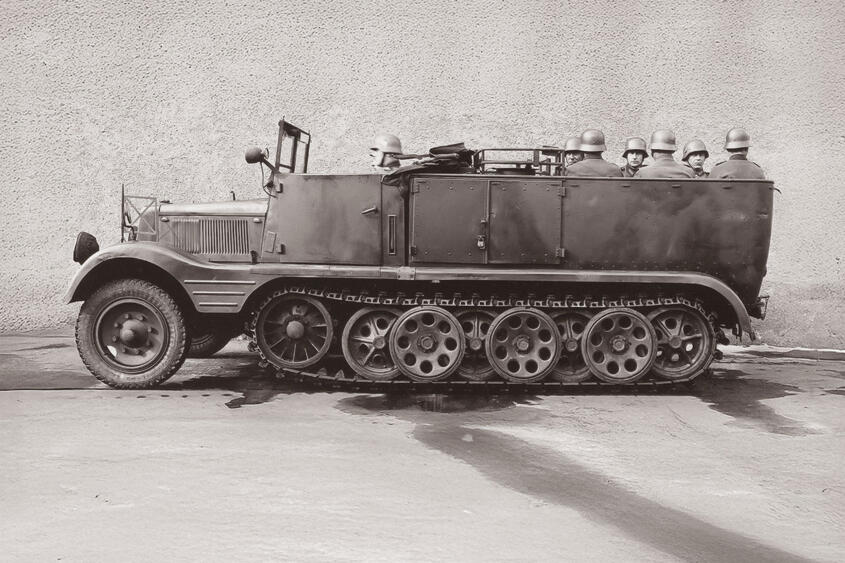

As early as 1926, Hansa-Lloyd engineer Heinrich Ernst Kniepkamp had developed a half-track tractor (called a “light tractor with a three-ton trailer load”) for the Reichswehr, which was initially equipped with a six-cylinder engine from Hansa Lloyd and later with an engine from Maybach. In 1937, the vehicle was given the designation Sonder-Kraftfahrzeug 11, or Sd.Kfz 11 for short. Around 500 vehicles of this type were produced by Hansa-Lloyd and Borgward. Later, it was also manufactured by Adlerwerke in Frankfurt am Main, Auto Union AG in Zwickau, and Škoda in Pilsen. From 1937 onwards, Borgward also had to produce the eight-ton half-track tractor Sd.Kfz. 7 (medium tractor) developed by Krauss-Maffei. The vehicle was also built by Krauss-Maffei in Munich-Allach, by Saurer in Vienna, and in small numbers by Krupp in Essen after Büssing and Daimler-Benz withdrew as manufacturers. By 1945, Borgward alone had produced 5,496 vehicles of this type, and even in February 1945, 53 units left the factory. A total of 4,785 workers, 65 percent of whom were forced laborers and prisoners of war, built these massive half-track tractors. From August 1944, around 1,000 prisoners from the Neuengamme concentration camp were also forced to work on production. In October, a heavy air raid crippled 75 percent of production, but work continued undeterred even after that.