The Borgward chronicle with Hansa-Lloyd from 1931, Goliath, and Lloyd

Page 2

By Christoph Büch and Steve St.Schmidt (2026)

Goliath in the 1930s

The Goliath with the highest payload was the 1.5-ton Superior, introduced in 1930, which was identical in construction to the Hansa-Lloyd Columbus model. Since no engine with the required power was available, a suitable 37 hp gasoline engine was sourced from Berg-Heckmann-Selve AG in Altena, Westphalia. With this engine, the Superior reached a speed of 65 kilometers per hour. The vehicle remained on the market for only a short time, because from 1932 onwards it seemed more sensible to market the Columbus from Hansa-Lloyd with the same engine and tonnage instead.

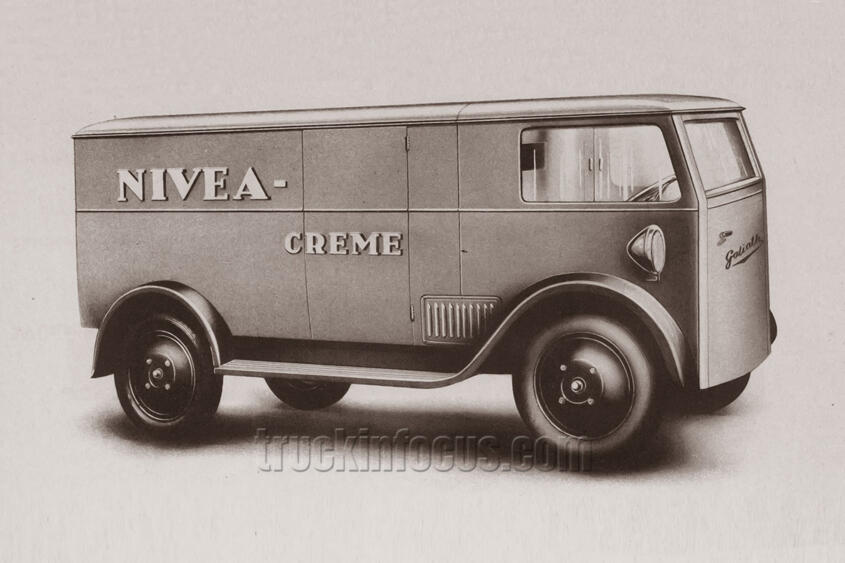

In 1932, the Goliath Atlas was introduced, a cabover vehicle with a payload of one ton. It was advertised as “the most modern fast truck in the world.” Based on the Goliath Express, to which it was very similar, it reached a top speed of 50 kilometers per hour with its 15 hp two-cylinder engine. The Atlas also had the entry door at the front of the vehicle. The company was particularly proud of the “comfortable, upholstered bench seat,” the signal button mounted on the “hand wheel,” and the Dyna starting system, which integrated the starter, alternator, and ignition. In the same year, the Rapid and Standard cargo motorcycles were given a new look, featuring a more modern rear wheel cover. Dynamically shaped horizontal beads on the sides characterized the new design. In 1933, the names Rapid and Standard were replaced by the type designations Z 200 and Z 400. The technical data remained unchanged, only the purchase prices rose slightly.

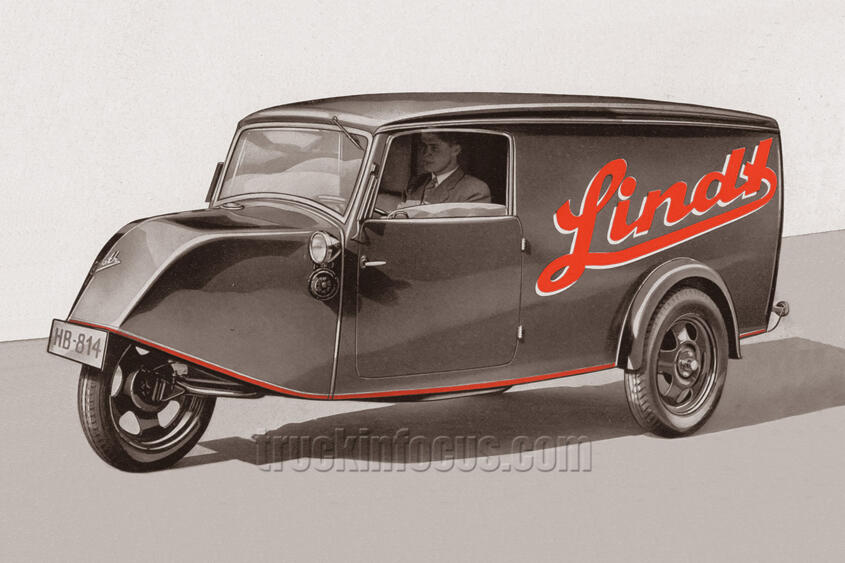

At the end of 1933, the F 200 (5.5 hp, 500 kg payload) and F 400 (10 to 11 hp, 750 kg payload) three-wheeled delivery vans were introduced. The rear wheels were driven by air-cooled two-stroke gasoline engines manufactured in-house (LE 200 P and F 400). The loading area was located behind the cab, and there were flatbed trucks, panel vans, and combination vehicles (i.e., both delivery trucks and cars). The purchase prices were 1250 and 1430 marks. In 1935, both three-wheeled models were given more modern cabs with sloping windshields. In 1936, the engine power was increased to 6.5 and 12 hp. The payload was now 680 and 930 kg and was increased again in 1937 (to 690 and 1010 kg). Until at least 1933, the F 200 model was exempt from tax and driver's license requirements, with transition periods finally abolished in 1937.

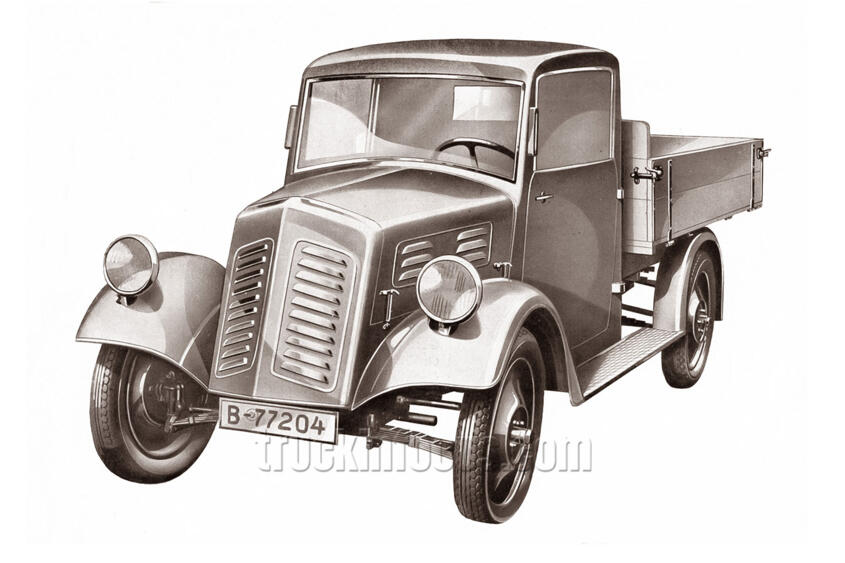

Another light commercial vehicle from Hansa-Lloyd-und-Goliath-Werke was the four-wheeled L 500 conventional truck with a 14 hp two-stroke gasoline engine and a payload of 750 kg, which was launched in 1934. At the end of 1934, it was given a new hood design. The cooling slots were replaced by fine-mesh grilles. In 1935, the L 500 became the L 600, which could be delivered with a variety of superstructures “for every purpose and every industry,” as the advertising slogan said. Its top speed was 55 kilometers per hour.

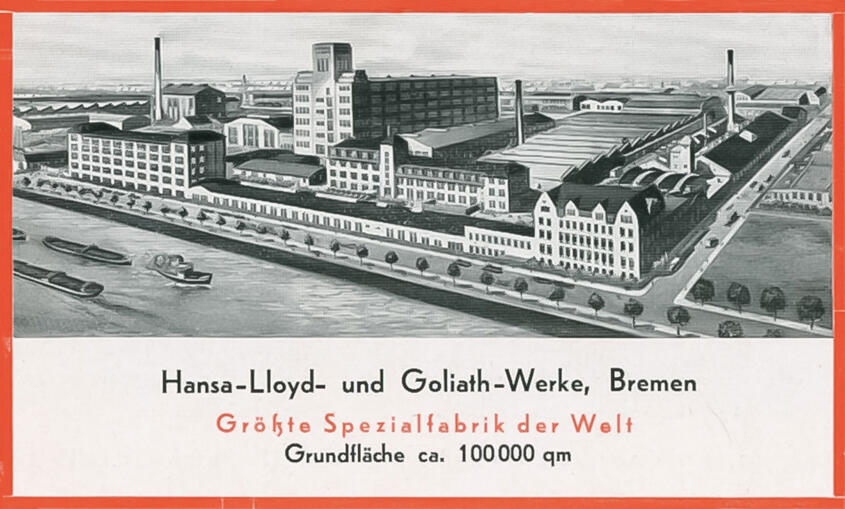

Over the course of the 1930s, additional locations were established: in addition to its headquarters in Bremen, Borgward invested in branch plants and supplier factories, for example in Osterholz-Scharmbeck, north of Bremen. There, special body components were produced and individual model series were assembled, in particular for later special-purpose vehicles and export versions. The logistical connection to the port of Bremen proved to be strategically valuable. Borgward also built a completely new plant in Sebaldsbrück, in what is now the Hemelingen district of Bremen, designed by Hamburg architect Rudolf Lodders. A modern factory complex surrounded by green spaces with bright, spacious rooms was built on an undeveloped 223,000 square meter site. The 1930s were marked by economic growth. Annual production rose from 4,210 vehicles in 1932 to 16,775 vehicles in 1936, while the workforce grew to 5,233 employees.

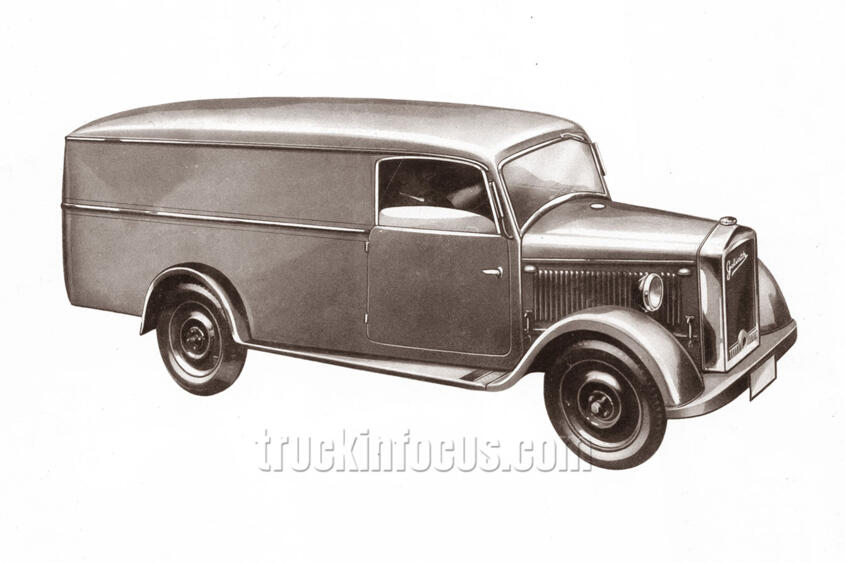

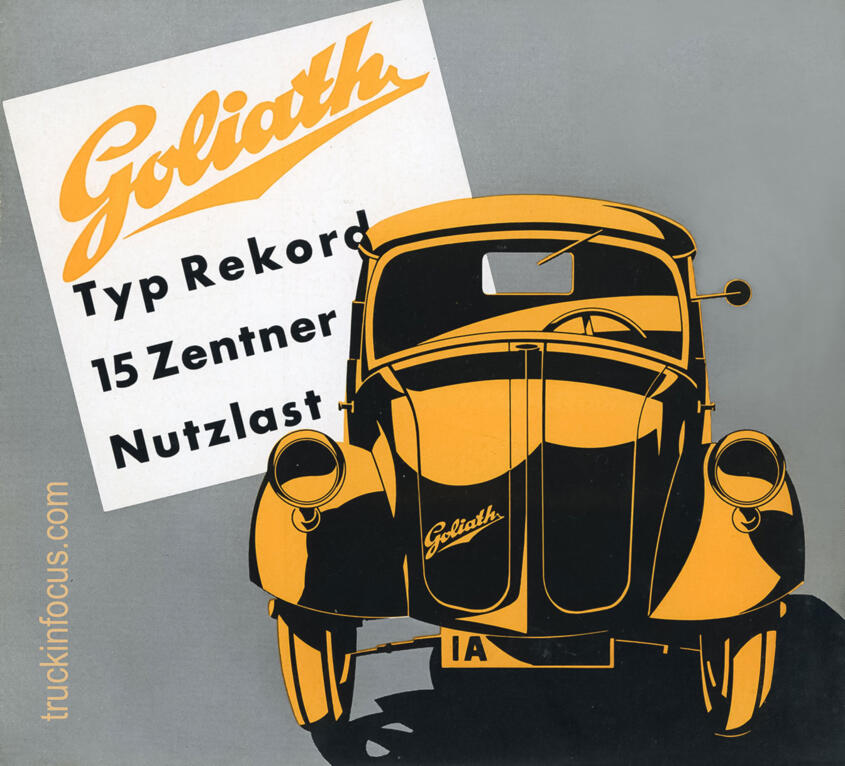

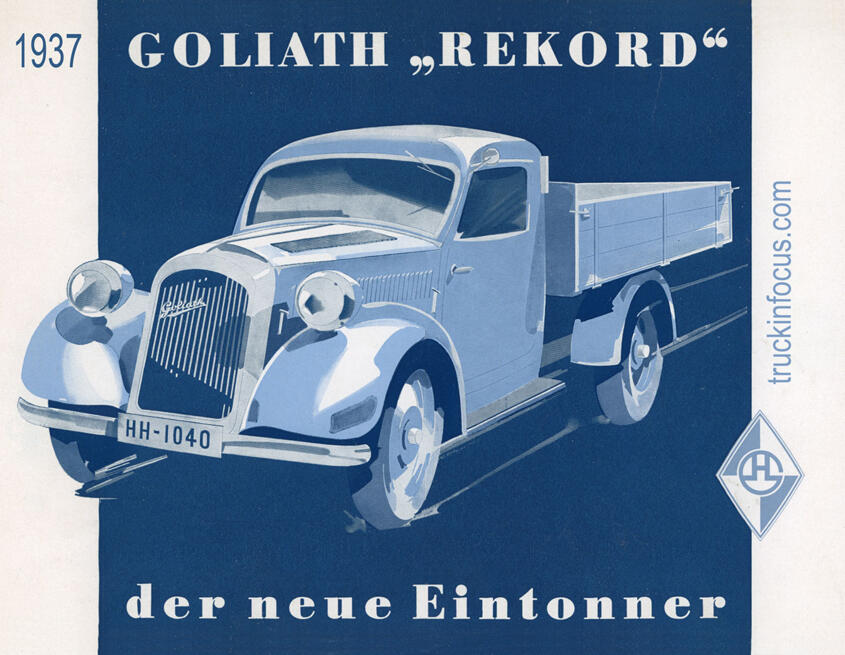

In 1935, the Atlas II model was introduced, replacing the first Atlas from 1932. The Atlas II was a conventional truck with an angular hood and a payload of one ton. The 600 cc engine with 18 hp enabled a top speed of 45 kilometers per hour. The Goliath Rekord was launched in the same year, initially equipped with a 14 hp two-stroke engine with two cylinders, which was located under the driver's seat. The round design of the hood had no openings and gave the three-quarter-ton truck a modern appearance with flowing lines. This changed as early as 1936, when a water-cooled, “lively and hill-climbing” four-cylinder engine with 24 hp was installed under the hood. In 1937, the name Rekord was replaced by “Goliath 1 to.” By decree of the National Socialist government, so-called “fantasy names” for commercial vehicles were banned and had to be replaced by combinations of numbers and letters referring to the payload. The measure served the purpose of war preparation, as the authorities responsible believed that a clear nomenclature was essential in an emergency.

In 1936, the company became a stock corporation, the “and” in the name was dropped, and the company was now called Hansa-Lloyd-Goliath-Werke A.G. However, this structure only lasted for one year. In September 1937, co-owner Wilhelm Tecklenborg left the company with a severance payment of four million Reichsmarks. His original investment in 1925 had amounted to 10,000 Reichsmarks. Borgward was now the sole owner of the company, which was henceforth called Hansa-Lloyd-Goliath-Werke Carl F. W. Borgward.

The last new releases from Goliath-Werke before World War II were the FW 200 and FW 400 three-wheeled delivery vans in 1938, which were identical in appearance. Their water-cooled single and two-cylinder engines with 6.5 and 13 hp were no longer installed under the seat, but under the hood, which now featured a radiator grille. However, production had to be discontinued in the same year because the government's Schell Plan imposed rigorous type restrictions on all German motor vehicle manufacturers. The production of three-wheeled vehicles was irrelevant for the impending war.