The Scania Chronicle

Page 2

By Christoph Büch and Steve St.Schmidt (Berlin 2023)

Concentration on commercial vehicles

In 1927, the factory finally made a modest profit. And the first six-cylinder engine was introduced, which produced 75 to 90 hp from a displacement of 1.53 Gallons, depending on the fuel quality. At the end of the 1920s, Scania-Vabis concentrated entirely on the production of commercial vehicles. The last passenger car left the Södertälje plant in 1929. At the same time, bus production gained in importance. The transport companies of several Swedish cities, including Stockholm, bought buses from Scania-Vabis.

In order to remain competitive with the emerging diesel engine, Scania Vabis turned to the development of the Swedish inventor and engineer Knut Jonas Elias Hesselman, whose engine design was a hybrid between a diesel engine and a gasoline engine. The Hesselman engine worked like an ordinary carburetor engine, but had direct petrol injection. It was lighter than a diesel engine and consumed less fuel than a conventional gasoline engine. The Hesselman six-cylinder engines with a displacement of 1.7 to 2 gallons produced 70 to 115 hp. Scania-Vabis used them to power commercial vehicles from around 1925 to 1936. The competitor Volvo also used Hesselman engines.

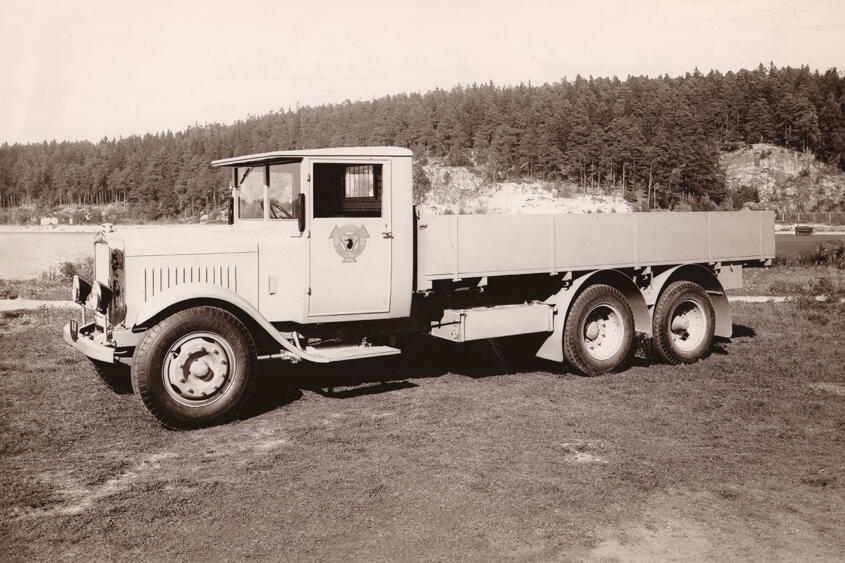

The economic crisis at the beginning of the 1930s led to another 60 percent drop in production. Nevertheless, the company did not lose sight of developments in commercial vehicle construction. In the following years, the engineers in Södertälje developed the first cab-over engine trucks, the so-called "bulldogs". The driver's cab was built around the engine and thus offered more usable space for goods and, in the case of buses, for more passengers. But the time was not yet ripe and the Bulldogs remained outsiders. By around 1940, 868 conventional trucks had been sold, but only 87 cab-overs (according to other sources, the number was 62), meaning that only around ten percent of customers were enthusiastic about the advanced design without a hood.

The Hesselman engines proved to be increasingly problematic. Carbon buildup gave rise to complaints. Scania-Vabis therefore decided to produce diesel engines even though there had initially been considerable objections to the rather rough-running direct injection engines. Pre-chamber diesels, on the other hand, ran much more smoothly and eventually won over those responsible in Södertälje. In 1935, Scania Vabis concluded a license agreement with the German company Humboldt-Deutz for the production of pre-chamber diesels. A new 2-gallon engine developed under this license produced 120 hp at 2000 rpm. The engine weighed 1323 lb. After some initial hiccups, the new engine proved its worth.

After surviving the recession, the 1930s brought a significant economic upturn for Scania-Vabis. Sales rose from 4.7 million kronor in 1932 to 10 million kronor in 1939, but compared to Volvo, Scania-Vabis was still a small manufacturer. A total of 103 trucks and 189 buses were sold in Södertälje in 1938. At Volvo, 2860 trucks and 288 buses left the factory in the same year.

During the Second World War, 90 percent of all Swedish commercial vehicles had to be converted to wood gas. An eight-cylinder engine with a displacement of 2.7 gallons was developed at Scania-Vabis, but it only produced 120 hp due to the poor efficiency of wood gas combustion.

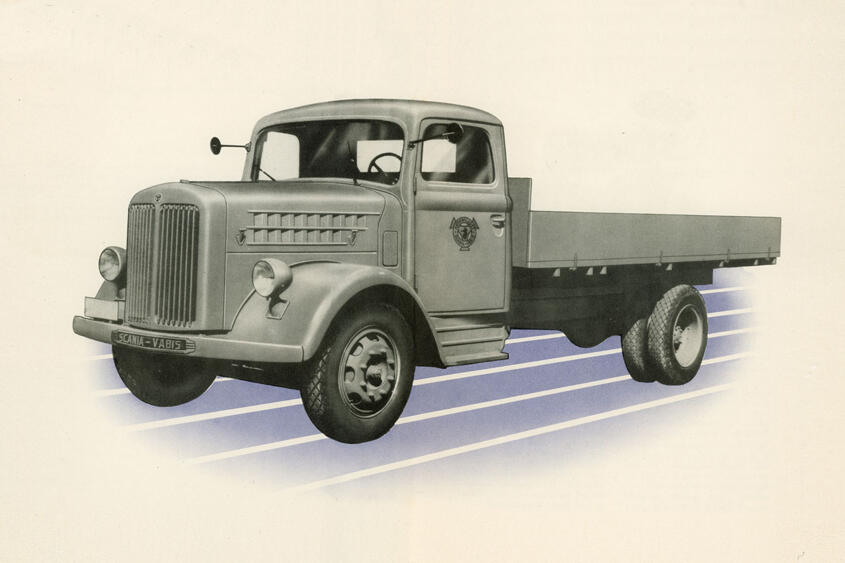

From 1944, Scania-Vabis offered the two-axle truck models L 10 (4x2) and F 10 (4x4). They were powered by a 1.5 gallon pre-chamber diesel with 90 hp. A carburetor version with the same displacement produced 105 hp. For the first time, a radiator grille with vertical struts protected the previously uncovered radiator. A total of 2398 units were built between 1944 and 1949.

New products after the Second World War

The production range was expanded very soon after the end of the war. Scania-Vabis presented new models as early as 1945: The L 11 and its variants L 12 and L 13 were distinguished by different wheelbases and were powered by the tried-and-tested four-cylinder diesel with 90 hp. Then came the L 21 and its variants L 22 and L 23 with a six-cylinder engine with a displacement of 2.25 gallons and 135 hp. All these trucks had two-axles, as well as the four-wheel drive versions F 11 and F 12 with four-cylinder engines and the F 21 and F 22 with six-cylinder diesel engines.

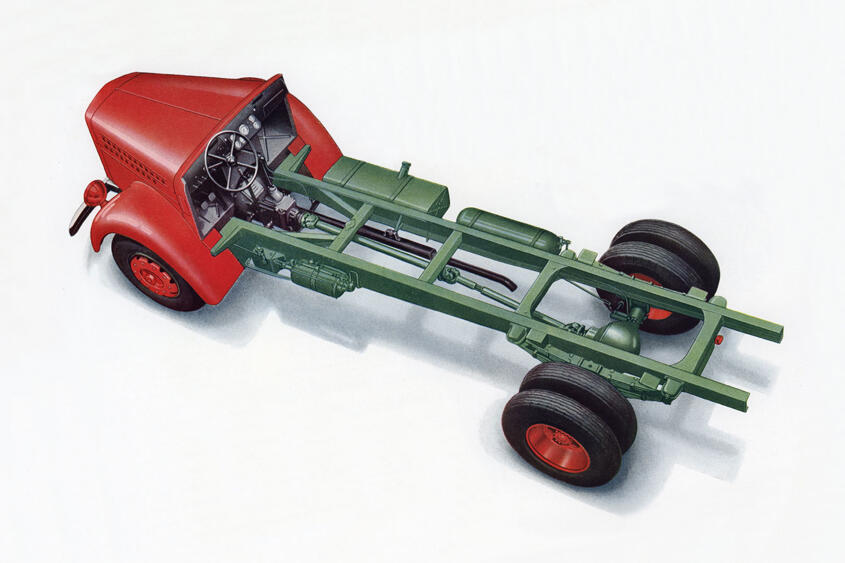

The two-axle trucks were designed for a total weight of eleven tons. A three-axle LS 20 reached up to 15 tons. The "S" on the three-axle vehicle stood for the trailing axle. A six-cylinder pre-chamber diesel with 135 hp served as the engine. The initially unsynchronized four-speed gearbox was synchronized after a few years and extended with an optional additional gearbox that doubled the gears. Hydraulic servo brakes were standard. Scania-Vabis offered its own cab in sheet metal-clad wood construction, but the trucks were also delivered with a bare chassis on request.

Bus and coach production remained an important pillar of the company. Worth mentioning, for example, is the advanced B 31 model with an eight-cylinder diesel engine with a displacement of three gallons and 180 hp. The bus had a self-supporting body, a semi-automatic Lysholm-Smith transmission and Bosch air brakes. Scania-Vabis buses were increasingly exported in the late 1940s.

Scania-Vabis also endeavored to expand its vehicle range, not least at the insistence of dealers. They also wanted to be able to offer passenger cars. The company succeeded in acquiring the distribution rights for Willys Overland and Volkswagen products. The income from Volkswagen sales was very important for Scania-Vabis in the 1950s. Willys Overland's sales figures were less convincing and the business relationship did not last long. However, Scania-Vabis remained the Swedish general agent for Volkswagen until 1968.

The need for more powerful and more economical engines led Scania-Vabis to abandon the pre-chamber diesel. In 1947, an agreement was concluded with the English company Leyland-Motors for the exchange of technical know-how. This gave access to the principle of direct injection. The first engines of this modern design were presented as early as 1949. The new engine family quickly proved its worth. The spectrum ranged from 1.5 gallons displacement and 90 hp to 3.3 gallons displacement and 200 hp. Thanks to improvements to the combustion chamber and injection system of the English engines, Scania-Vabis even managed to outperform the original. Important truck models of this period from 1949 onwards were the L 40 for 9 to 10 tons gross weight, the L 60 for 10 to 12 tons and the LS 60 for 16 tons, followed by other models with higher capacities and increasing type designations. It was now possible to offer long-lasting engines with lower maintenance costs than those of Leyland.

How do you open the hood?

The new unit was significantly more durable and economical than the previous pre-chamber diesel and became well known in the transport industry as the „250.000-mile engine". Scania-Vabis rewarded owners with a certificate and a badge for the radiator grille when they had covered 250.000 miles without repairs. In the first half of the 1950s, more than 1.350 such awards were presented, with the trucks often achieving far higher mileages of over 400.000 miles. A telegram to the customer service manager at Scania-Vabis was legendary: "Drove 250.000 miles. How do you open the hood?"

The truck line of the 1950s began with the L 40 series, powered by a four-cylinder direct-injection engine with a displacement of 1.5 gallons. A synchronized five-speed gearbox came as standard, which could be extended to ten gears on request with an additional gearbox. A six-cylinder diesel with 135 hp was used in the L 60 and LS 60 models. The "S" still stood for the trailing axle of the three-axle models. In 1951, Scania-Vabis also produced five units of the three-axle LS 85 model, which was powered by an eight-cylinder engine with a displacement of 2.25 gallons. However, no more were produced, as the weight distribution proved unfavorable - the elongated engine was too heavy at the front.

The export of vehicles became increasingly important. The main customers were initially the neighboring Scandinavian countries and the Benelux countries, but significant quantities were also exported to the Middle East and increasingly also to Latin America. As early as 1951, 25 percent of production was destined for export. On the domestic market, Scania-Vabis was able to successfully compete with its rival Volvo with a market share of 40 to 50 percent. In the heavy-duty class, the market share was as high as 70 to 75 percent.

In the spring of 1953, the model series were given names for the first (and last) time. The L 51 with a four-cylinder diesel engine and 100 hp was given the name "Drabant". The L 71 / LS 71 series with a 150 hp six-cylinder engine was christened "Regent". From 1955 air brakes were standard and power steering was also available. 7.800 Regent models were built from 1954 to 1958. These trucks still had the hood side panels of the 1940s and free-standing headlights on the mudguards.