The Rotterdam Multi-Trailer System

How FTF mastered container movement in the terminal

FTF, the Dutch manufacturer of trucks and special vehicles, was known for individual solutions in the construction of particularly heavy units. When container traffic became established internationally, methods had to be developed in a short time to transport the standardized large containers in the port. Europe's first container terminal was built in Rotterdam in 1966. FTF supplied the tractor units with which trailer trains up to 330 feet long could be moved in the port area. In this article, Niels Jansen from Bergen in North Holland describes how the development progressed and what has become of some of the FTF port tractors.

The port of Rotterdam is the gateway to the European continent. It has always been of great importance to the economy, but even more so since the first container shipments began in the mid-1960s. The method of transporting goods in standardized steel boxes conquered the world, and 1966 saw the opening of the Europe Container Terminal (ECT) in Rotterdam. In the first year, just under 10,000 containers were handled there, and three years later the figure was already more than 100,000. After signing a contract with the U.S. container shipping company SeaLand (now Sealand, a division of Maersk), the huge Delta Terminal was built directly on the North Sea coast in 1988.

A new port transportation system also began operating in the late 1980s. It consisted of heavy tugs capable of moving nearly 330-feet-long rubber-tired trailer trains. At the ECT, it was given the name multi-trailer system (MTS) or trolley system. Since conventional terminal tractors could not handle the gross loads of 250 to 300 tons, the ECT planned to invite bids to build a tractor with a 6x4 drive formula and a minimum 400-hp diesel engine and automatic transmission.

In 1979, the container terminal placed an order with heavy vehicle manufacturer Floor Truck Company (FTF) to build a prototype to be tested under real working conditions. DAF and Mercedes or Titan also received corresponding orders to build prototypes with which they would compete for the lucrative series production.

In addition, a large number of trailers with drawbar frames were needed at the ETC. The development of the first four-wheel steer units took place at DAF. However, the subsequent orders went to the Dutch machine manufacturer Buiscar from Apeldoorn. This company had a long tradition of building trailers for internal transport. The system, initially developed for the container terminal, was later also available commercially. It consisted of trains with a maximum of ten trailers coupled together, pulled by heavy tractors. All trailers were self-steering and self-braking and had automatic couplers. The truck driver therefore did not have to leave his cab.

The entire system was designed primarily to save time, a priority in container handling. In 1980, Floor received an order to supply two tractors to be tested under actual working conditions. FTF supplied the FD-8.20D1 tractor with a 6x4 drive formula. It was equipped with a Detroit two-stroke diesel engine type 8V92TA. Power was transmitted by a four-speed Allison HT750DRD automatic transmission to a GNK-Kirkstall rear tandem. According to the data sheet, the V8 turbo engine produced 461 hp, but was reduced to 414 hp in the version for the container terminal. This was to prevent insufficient traction when starting up with a loaded train and the wheels spinning, for example in wet conditions. When empty, the speed was limited to 18,6 mph and to 12,4 mph for weights over 150 tons.

Test runs with the first multi-trailer train took place on a specially rented area at Rotterdam Airport. After these trials proved successful, a contract was signed with Floor in 1985. Subsequently, FTF delivered 15 new FD-8.20D1 model tractors for the operation of the Delta terminal, which had just opened. The vehicles proved so successful that a follow-up order for five more was placed three years later. These were fitted with Kessler axles rather than Kirkstall axles at the rear.

As the worldwide use of containers increased, another series of FTF tractors was added to the port fleet between 1991 and 1994. These similarly equipped tractors featured some marginal changes such as a new grille. Including the prototypes, Floor built a total of 40 units for the terminal. All vehicles were equipped with a ballast box that could hold two concrete blocks with a total weight of 14 tons. They also had a heavy-duty front bumper, a special trailer hitch, and a sturdy steel cage above and behind the cab to protect the driver. It is reported that at least one FTF tractor suffered a total loss when a loaded container fell from a port crane.

Only four of these legendary FTF tractors have survived. One is in the port of Abu Dhabi, a second is in the shed of a Belgian truck collector, and the other two are part of Ton Spaansen's FTF museum in the Dutch town of 't Zand. Spaansen's interest in Floor products dates back to 1973, when the family transport company bought an FTF truck and trailer to haul sand, bricks, shells and building materials. The now ex-company boss, born in 1947, recounts: "When I was 25 years old, I drove the rig about 625 miles to Belgium and back every day to transport stones from a mine. I just loved it - I was especially fascinated by the sound of the roaring V8 engine when going uphill. After three years, we bought another FTF three-axle truck, but because I had another job to do in the company, my family decided to give it away again a short time later. Almost 20 years later, I happened to come across that very truck and bought it right back. That was the beginning of my hobby, the restoration of old commercial vehicles.

A few years later, my wife Ans and I founded the FTF Club and in 2006 our FTF Museum. There, the two former ECT tractors and a huge FTF dump truck that was once in use at a nearby steel mill stand out the most. "It wasn't easy to get these rare beasts," Ton says. "Both ECT and the steel mill are international companies, and I had to negotiate with different CEOs. And it also needs luck. In 2003, we learned that the terminal was going to retire almost all of its container tractors, and we were lucky enough to get unit number 940. The vehicle was not only the last tractor ordered by the ECT from Floor, but also the last FTF ever built before the truck manufacturer closed its doors for good in 1994.'' This tractor is displayed in the museum as it was found.

Five years after Spaansen acquired the last FTF-built vehicle for his museum, the ECT took the only remaining working FTF in Rotterdam, number 936, out of service. The museum managed to acquire this one as well. In recent years, it has been refurbished by Ton Spaansen with the help of mechanic Klaas Poutsma. However, some trim work on the ballast box as well as sandblasting and painting of the entire vehicle was contracted out to a professional body shop. The intention is to also present the rare FTF at classic car meetings, but that sounds easier than it is. With a top speed of only 18,6 mph, any longer drive with it is quite a challenge!

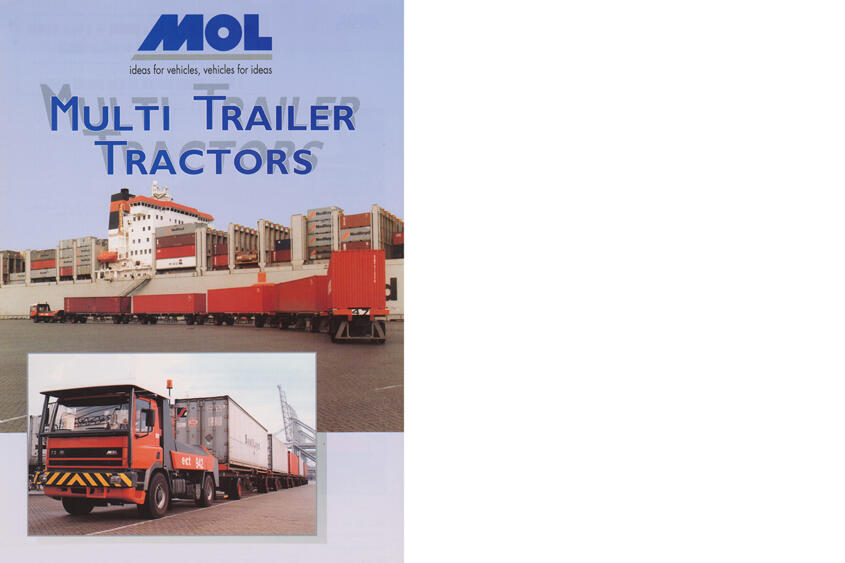

The question remains as to what was acquired at the container giant ETC after the FTF period to move the containers around the terminal. Well, they knocked on the door of Belgian specialty truck and trailer manufacturer MOL in Hooglede. MOL was known as a manufacturer of terminal and ro-ro tractors. After the company was asked to develop a tractor unit adapted to the special requirements, the TG280 with 4x4 drive was presented. This custom-built tractor was equipped with a 430-hp, six-cylinder, 12.6-liter DAF diesel coupled to an Allison HD4060 automatic transmission and a Steyr VG 2001 transfer case. The Kessler axles had load capacities of 16 tons front and 25 tons rear. The CF cab was also from DAF.

Later versions of this rugged, compact workhorse were fitted with Renault or Iveco cabs, and engines now used are Cummins, Iveco and Volvo diesels. The fully automatic trailer hitch has been retained on MOL's TG280 tractors. The container terminal has purchased several dozen of these terminal tractors. They can move container trains with up to seven trailers and a maximum gross weight of 350 tons. But as powerful as they are, the engine noise of the MOL tractors doesn't come close to the sound produced by a roaring V8 Detroit Diesel at full power.

Text: Niels Jansen

Photos: Niels Jansen Collection