Construction Machinery Pictures

German construction machinery of the post-war period

We are venturing into unfamiliar territory with this article. Construction machinery is not really our subject, but in some respects trucks and construction equipment are closely related. The archive of Edition Diesel Queen, from which truckinfocus.com draws a large part of its content, also contains thousands of construction machinery images from many countries. We have put together a small selection of advertising material and photos showing machines that were in use on German construction sites in the 1950s and 1960s. Most of the manufacturers of the machines no longer exist, but we have been able to gather some information through painstaking research. We make no claim to completeness, especially as there were many other manufacturers, which we will perhaps present in a sequel.

Construction machinery designers have come up with some amazing things over the past few decades. It is fascinating to see how some concepts are coordinated and how certain ideas are repeated over time. Engineers with intuition, expertise and foresight have ensured that new equipment has been designed and developed to series maturity time and time again. The driving force behind all these innovations is the intention to make heavy work easier, to relieve people and to increase efficiency. In this article, we take a look at German construction machinery technology in the decades following the Second World War. Some machines have long since been forgotten or are technically obsolete, while other designs form the basis for technologies that are still in use today. The following article contains more than sixty photos and advertising materials on the subject of construction machinery used on German construction sites in the 1950s and 1960s. We have compiled information on the individual manufacturers and equipment in the text. If you would like to see many more pictures and information on this topic, you should visit the German Internet forum baumaschinenbilder.de

Bischoff-Werke KG, Recklinghausen

The Polytrac 1200 (1954–1966) was marketed by Bischoff-Werke KG, then located in Recklinghausen, as a universal construction machine. There was an air-cooled version (HL 1200) with a 46-hp Deutz engine and a water-cooled version (HW 1200) with a 40-hp engine. The machine could be adapted to various requirements. In addition to its use as a wheel loader, it could be equipped with a swing bucket, rod grabber, stone fork, backhoe bucket, dozer blade, and a boom with a crane hook. The components were easily interchangeable and could be transported on a trailer. Even clip-on tracks instead of front wheels were available. The 6.5-ton Polytrac had a maximum speed of 25 km/h (15.5 mph).

This image shows the final version of the Bischoff Polytrac HL 1200 from 1966, featuring a closed cab and equipped with a boom and grabber. In the mid-1960s, Bischoff faced financial difficulties and discontinued its construction equipment division in 1970.

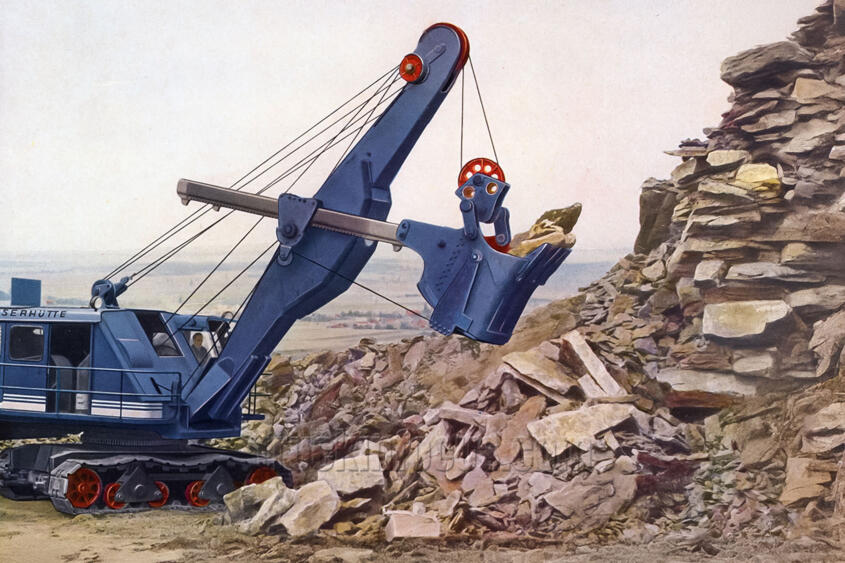

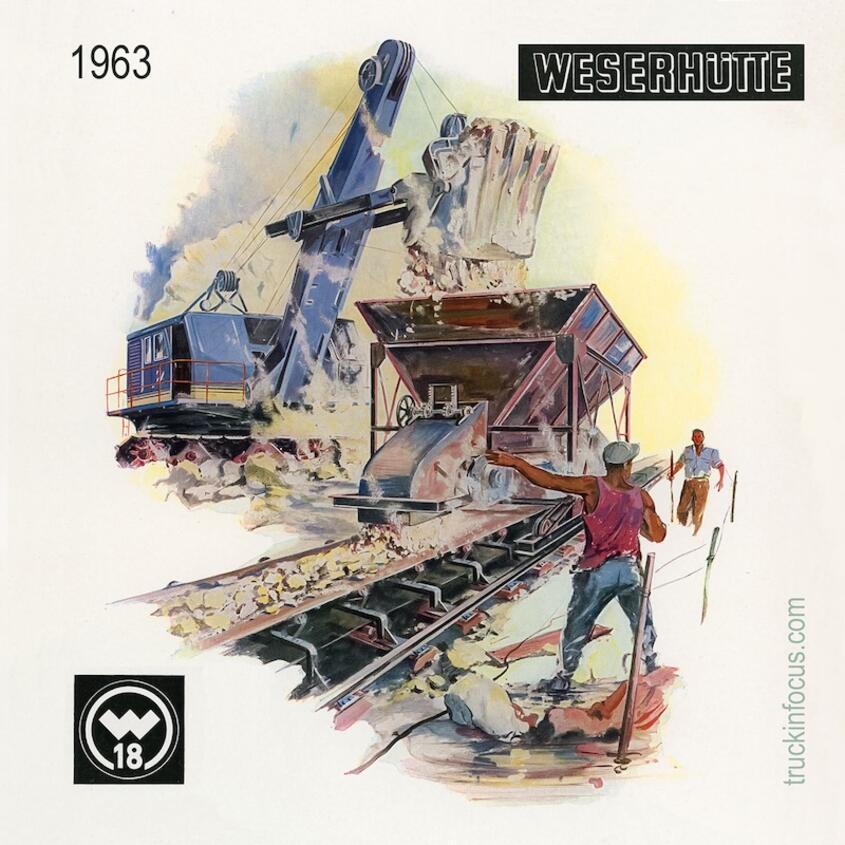

Weserhütte GmbH, Bad Oeynhausen

The Eisenwerk Weserhütte Otto Wolf GmbH was founded in 1844 in Bad Oeynhausen. During World War II, the company produced heavy guns, armored reconnaissance vehicles, and infantry fighting vehicles. In the 1950s, Weserhütte began manufacturing cable-operated excavators and became an international market leader in this segment. Despite its dominance, the company faced financial difficulties in the early 1970s, and after years of unsuccessful stabilization efforts, Weserhütte went bankrupt in 1987. The two presumably hand-colored photos come from a Weserhütte brochure from 1963. The images show the W 18 universal crawler excavator with a high bucket (top) and as a clamshell excavator used in road and industrial construction.

Illustration from a 1963 Weserhütte brochure, featuring an excavator of type W 18.

Klöckner-Humboldt-Deutz AG (KHD), Cologne

The Deutz DK 60 crawler bulldozer, powered by an air-cooled Deutz Diesel F 4L 514 (60 hp), was built from 1953 to 1959. The machine featured five forward and three reverse gears, with a top speed of 7.5 km/h (4.7 mph). The unit shown in the image is equipped with a Menck dozer attachment.

This Deutz DK 120 crawler bulldozer from the early 1960s was fitted with a Meiller front loader, model 1701 D2, featuring a bucket capacity of 1.75 cubic meters (2.3 cubic yards).

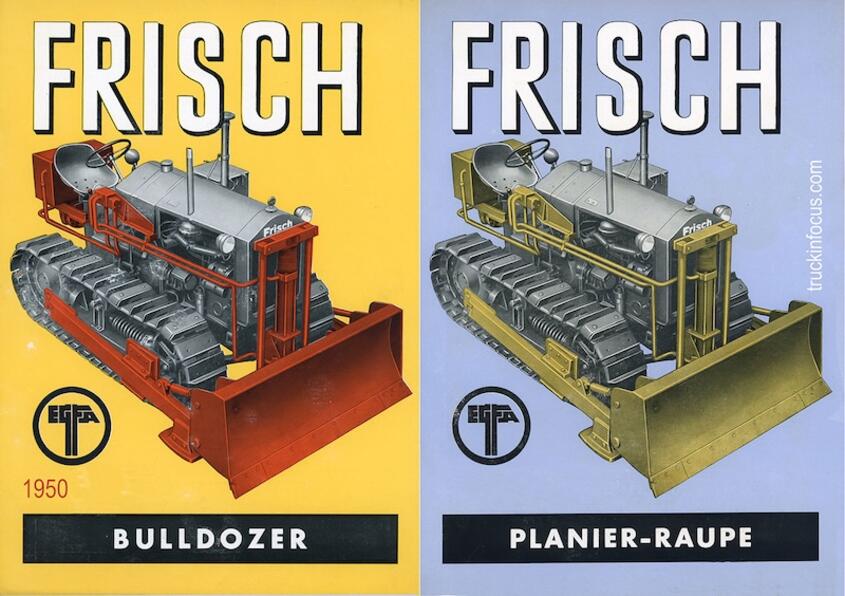

Heinrich Frisch KG, Augsburg

The Ironwork Company Frisch Brothers Augsburg, founded in 1902, was a German steel and mechanical engineering company that changed its legal form multiple times after 1913 and was renamed Frisch GmbH in 1971.

In addition to producing steel structures, Frisch began developing road construction machinery in 1926. In 1936, the company introduced a machine called Augusta, which was the first motor grader manufactured in Germany. Business remained strong during and after World War II, and the company continued to develop and produce construction equipment.

At the time, Frisch had a close partnership with Hanomag, supplying bulldozer blades for their crawler tractors. The illustration shows the English and German versions of a 1950 brochure cover, featuring a Hanomag crawler tractor with Frisch attachments - however, the Hanomag logo is missing. Presumably the name Frisch was retouched in here. Menck & Hambrock

proceeded in a similar way.

In 1977, the struggling company was acquired by FAUN-Works, which then established FAUN-Frisch Construction Equipment Ltd. In 1986, FAUN-Works and FAUN-Frisch Construction Equipment Ltd. were incorporated into the O&K Group. In 1998, Fiat’s subsidiary New Holland acquired O&K’s construction equipment division and completely shut down production at the former Frisch factory in 1999.

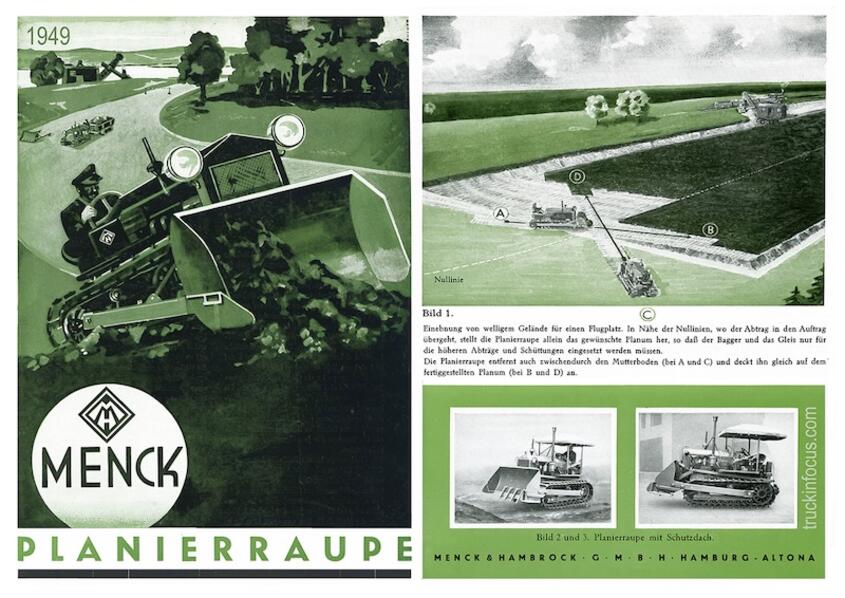

Menck & Hambrock GmbH, Hamburg-Altona

The Universal Excavator M 152 by Menck & Hambrock from Hamburg-Altona was based on the pre-war model Mb (1933 to 1945) and was built from 1949 to 1961. The name "Universal Excavator" was well deserved, as it could be equipped with all common working attachments of the time, such as a high bucket, deep bucket, lattice boom with dragline or grab, pile driver, crane, or grading bucket. The photo shows the approximately 44-ton cable excavator loading a tipping railcar. These narrow-gauge railroads were an indispensable means of transportation, especially in the period after the Second World War, for clearing the rubble in bombed-out German cities.

Another Menck Universal Excavator M 152 is seen here, working as a high bucket excavator to load an articulated Euclid Earth Mover with bottom discharge, whose presence on a German construction site remains unclear. In the background, a Krupp Gigant AMK awaits its turn to be loaded.

The M 90 cable excavator was built by Menck & Hambrock from 1955 to 1970. The photo shows a model with a high bucket loading a Zettelmeyer dumper. The M 90 weighed nearly 27 tons and was equipped with engines ranging from 90 to 115 horsepower.

After World War II, Menck & Hambrock produced around 25 different cable excavators. The M 60 model was available from 1954 to 1972. The photo shows it loading an American truck (probably a GMC CCKW). These former military vehicles were widely distributed to the German construction industry after the war, where they were urgently needed for reconstruction. The partially open U.S. driver cabs were replaced in Germany with closed versions, as seen in this example.

Menck & Hambrock also had bulldozers in their product line at times. A 1949 brochure, from which the cover page and an inner page are shown here, contains the phrase: "The bulldozer drives itself off the railway wagon to the construction site at a speed of 7.8 kilometers per hour, where it operates freely, flexibly, and quickly like no other excavator, moving back and forth in any direction as needed, and working on slopes up to 1:4." The approximately six-ton machine was powered by a Hanomag four-stroke engine of type D 52 with 50 horsepower. The brochure does not mention that the Menck bulldozer was essentially a Hanomag K 50 crawler tractor with a Menck-produced blade attachment.

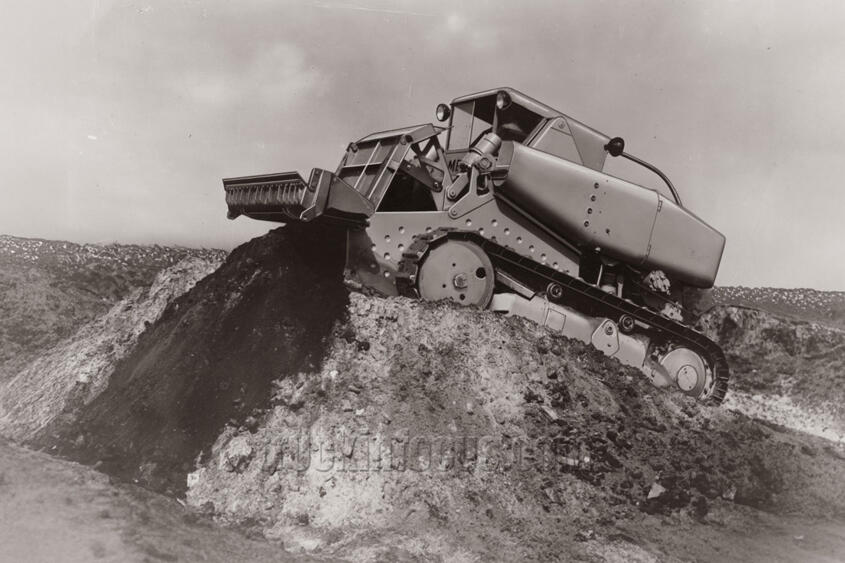

Menck & Hambrock also produced the SR 53 scraper dozer (named after its birth year, 1953), powered by a 120-horsepower Deutz Diesel A6 M 517. The photo shows the unusual machine emptying its bucket "head-on" on an incline. Scraper dozers were a "combination of the tracked chassis of a bulldozer and the raisable and lowerable scraper bucket of a motor scraper" (Wikipedia). The bucket's rear wall could be hydraulically pushed forward to empty its contents. The SR 53 was a further development of the SR 39 from World War II. The SR 53 was followed by the SR 65 and the SR 85 in 1969, with their model names indicating bucket capacities of 6.5 and 8.5 cubic meters, respectively.

Menck scraper dozers were expensive to purchase and maintain, but according to Wikipedia, a scraper dozer in earthmoving operations could replace a hydraulic excavator, two to four trucks, and a bulldozer. However, operating the machine required highly skilled personnel, as mastering it took considerable time. Scraper dozers are still manufactured today by the Swiss company Frutiger Baumaschinen & Co. The latest development is the S 3000 Tiger with an 18-cubic-meter bucket.

Menck scraper dozers were expensive to purchase and maintain, but according to Wikipedia, a scraper dozer in earthmoving operations could replace a hydraulic excavator, two to four trucks, and a bulldozer. However, operating the machine required highly skilled personnel, as mastering it took considerable time. Scraper dozers are still manufactured today by the Swiss company Frutiger Baumaschinen & Co. The latest development is the S 3000 Tiger with an 18-cubic-meter bucket.

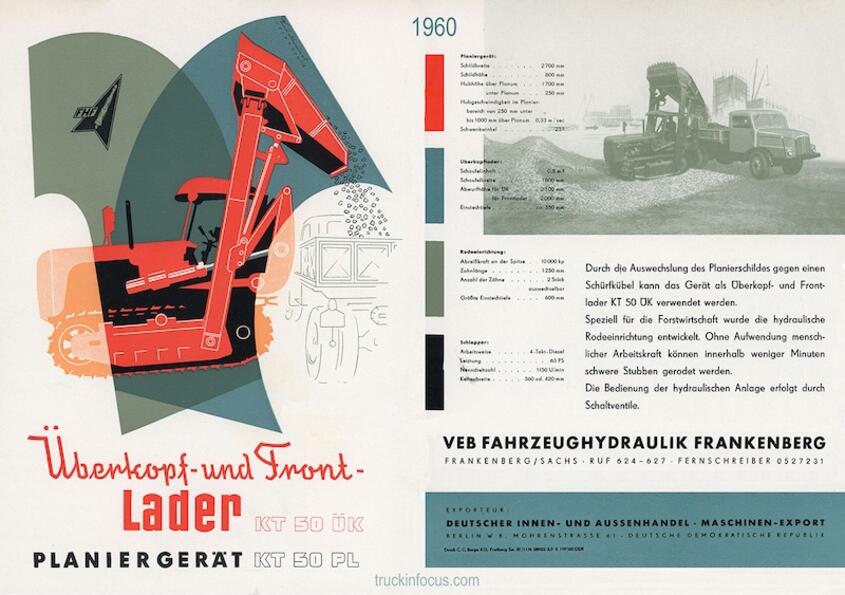

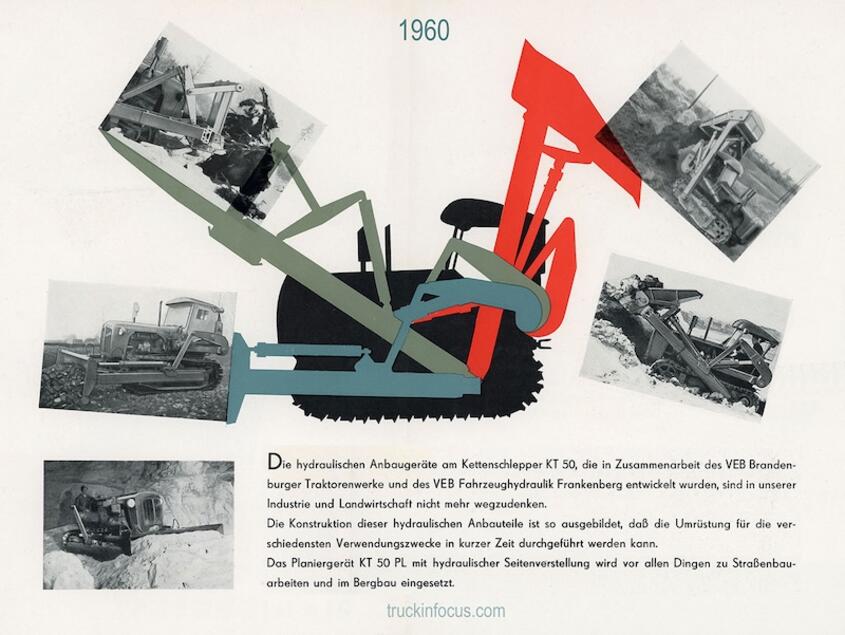

VEB Frankenberg, Frankenberg

The images shown here come from a 1960 brochure, with the outer pages on top and the inner pages below. With appealing graphics from that era, the products of the state-owned enterprise (VEB) Fahrzeughydraulik Frankenberg were advertised, although only the attachments were manufactured there, while the KT 50 crawler tractor was produced by VEB Traktorenwerk Brandenburg in Brandenburg on the Havel. The overhead loader KT 50 ÜK and the grading device KT 50 PL were widely used in road construction in East Germany. The KT 50 was based on a crawler tractor from the Famo-Werke dating back to around 1935, which was further developed visually and technically in the GDR. Frankenberg had been home to the Fahrzeugwerk Hunger since 1948, one of the largest private companies in East Germany, until it was nationalized in 1958 after its founder, Walter Hunger, emigrated to the West to start anew.

Nordtrak, Hamburg

The North German Tractor Factory Franz Westermann, abbreviated as Nordtrak, produced agricultural and forestry tractors as well as construction machinery in Hamburg between 1947 and 1957. A distinctive feature of Nordtrak products was the all-wheel drive with four equally sized wheels, which was unusual at the time and based on the drivetrain technology of the American Jeep. Pictured here is a Nordtrak Stier 480 with the 48-horsepower MWM AKD 12 V diesel engine. A hydraulic Meiller overhead loader was used to load a trailer.

Wilhelm Stöhr, Offenbach am Main

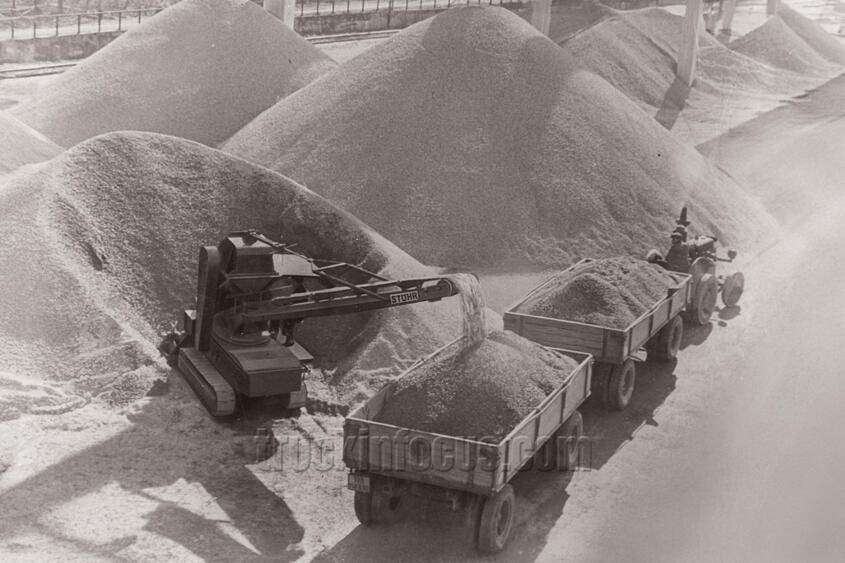

In the past, excavation material was usually transported out of construction pits or used to load trucks via conveyor belts, especially when no other equipment was available. Even better were the self-loading machines made by “Wilhelm Stöhr Factory for Transportation Systems and Elevators” from Offenbach am Main. The company was active from 1900 to 1970 and, for example, offered the world’s first mobile conveyor belt in 1922. Pictured here is the Stöhr Small Loader LK from 1955, with a conveying capacity of 35 cubic meters per hour, loading a tipper truck.

This photo shows the self-propelled Stöhr Self-Loader with a crawler chassis and a swiveling and height-adjustable discharge belt, loading trailers. The conveyor capacity was around 50 tons per hour. A Lanz Bulldog tractor with solid rubber tires can be seen as the towing vehicle. The photo, issued in the 1950s, likely dates back to the pre-war era.

The Stöhr “Self-Loader” appears significantly more modern in this photo, which dates from around 1955. The Self-Loader was available as Type LR with a conveying capacity of 60 cubic meters per hour and as Type LG with 90 cubic meters. It is difficult to determine the make of the truck currently being loaded with coke.

Wieger

Another machine that was used similarly to the Stöhr self-loader was the Wieger self-loading machine BST 60, which featured an electric or diesel-electric drive. Its capacity was 60 cubic meters per hour. Both photos, dated 1956, show the voracious machine in slightly different versions. Unfortunately, no further information is available - neither about the Wieger company nor additional details on these seemingly little-known machines.

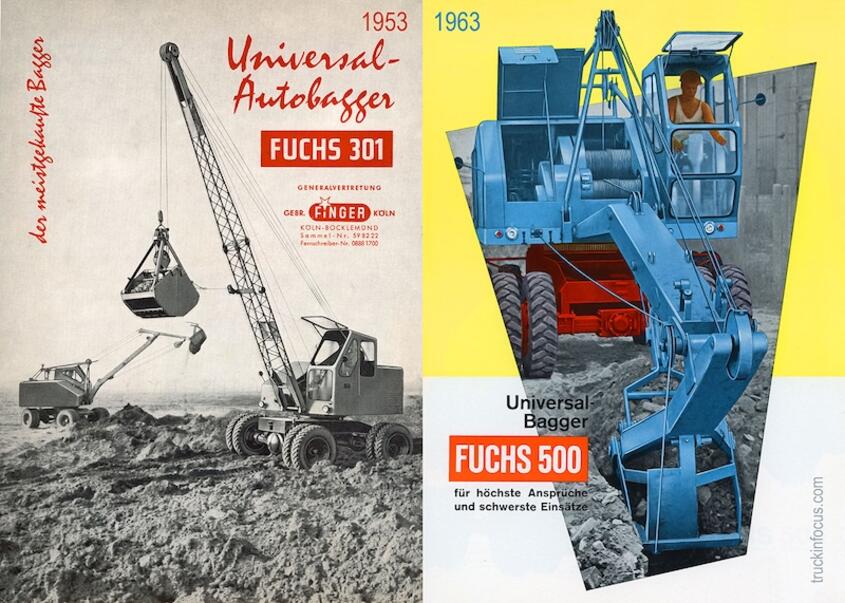

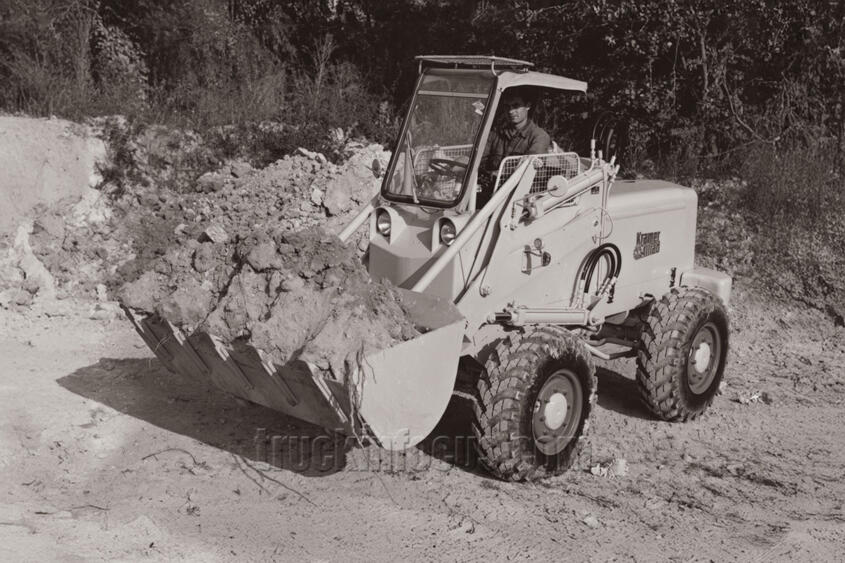

Johs. Fuchs AG, Ditzingen

Excavators from Johannes Fuchs, a company based in Ditzingen near Stuttgart, were an essential part of West German construction sites. In 1957, the company - founded in 1888 in Hemmingen - introduced the cable excavator series 301. With more than 15.000 units produced, the Fuchs 301 is considered the most-built excavator in the world until production ceased in 1978. The photo shows the machine with a 300-liter clamshell bucket, while in the background, a version with a backhoe bucket can be seen. The backhoe was available in cutting widths of 700 and 800 millimeters.

The Fuchs 301 with a dozer blade was used for backfilling trenches and leveling loose soil. The width of the blade was 125 centimeters. Additionally, the machine could be equipped with a high-level bucket, a multi-shell grab, a special bucket for digging drainage and cable trenches, a dragline bucket attachment, and even a ten-meter-high construction crane. The undercarriage was available with either all-wheel or rear-wheel drive, and the total lifting capacity was 22 tons.

Various Fuchs brochure covers from around the 1960s show the 301 and 500 models with different working attachments.

Friedrich Heinrich Flottmann GmbH, Herne

In the year 1961 a Flottmann crawler compactor Vibrotrek R 42, equipped with six individual compaction plates, smooths the surface of what is now the A40 highway in Germany. Today, over 100,000 vehicles use this road daily - when they are not stuck in traffic between Essen and Dortmund. The Friedrich Heinrich Flottmann mechanical engineering company, founded in 1872, ceased operations in the late 1980s.

Borco

The Borco vibratory compactor Vibrofix TR 50 from 1962 was powered by an air-cooled Faryman four-stroke diesel engine with 14 HP. Devices of this type are also referred to as plate compactors. No information was found about the Borco company and its location in Germany.

Hatra, Travemünde

The machine factory Alfred Hagelstein, founded in 1919 in Travemünde, is best known under the name Hatra. The four-ton Hatra SL125 swing loader from 1961, equipped with a 1.5 to 1.8 cubic meter bucket, featured a 360-degree swiveling loading system, allowing it to scoop, load, and unload from the side. It was powered by an air-cooled Deutz V6 diesel engine F6L 714 with 125 HP. The unusually high maximum speed of 42 km/h for a construction machine, combined with all-wheel drive and all-wheel steering, made the Hatra SL125 particularly powerful and maneuverable. It was used by the German army as an engineering vehicle, which acquired more than 1650 units from Hatra between 1961 and 1964. About 300 units were sold to the civilian construction industry under the designation SL 225. Hatra ceased its construction machine production in the early 1970s after 53 years.

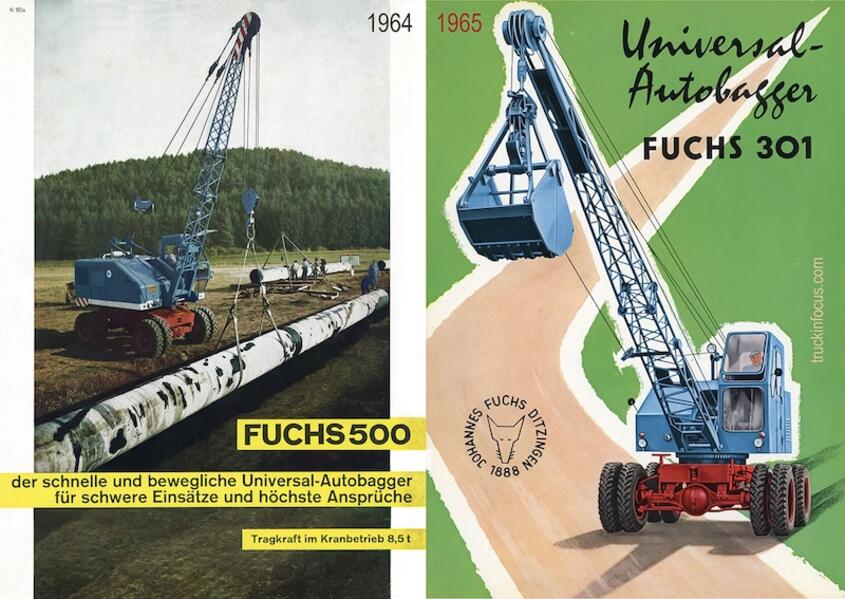

Rudolf Dolberg AG, Rostock, Berlin and Dortmund

Rudolf Dolberg AG, founded in 1884 and based in Rostock, Berlin and Dortmund, was originally a manufacturer of tracks, switches and other narrow-gauge railroad accessories. Construction machinery was added around 1935. In the 1950s, the M 200 crawler excavator became the best-selling small excavator in Germany thanks to its robust design and transport weight of just six and a half tons. In 1960, the Krupp Group took over the company and continued to run it under the name Krupp-Dolberg. The D 200 M wheeled excavator was now intended to compete with the successful Fuchs 301 in the six-and-a-half-ton class, but did not succeed to the extent hoped for. Excavator production at Krupp-Dolberg ended in 1969, after an attempt to halt the downward trend with a hydraulic excavator in 1965.

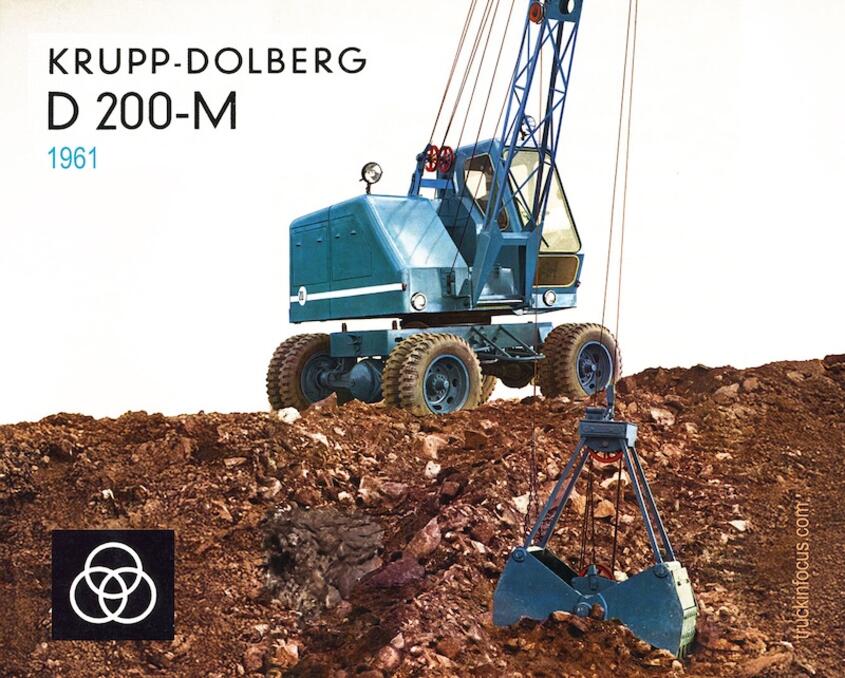

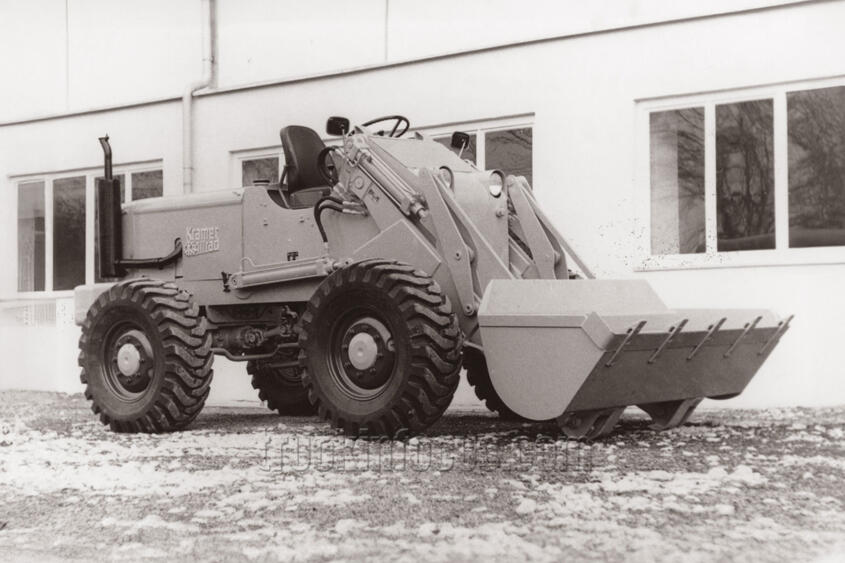

Kramer-Werke GmbH, Gutmadingen

Today, Kramer-Werke GmbH is based in Pfullendorf. The company was founded in Gutmadingen in 1925 and began producing farm tractors. Road tractors and trucks were also part of the portfolio after the Second World War. Around 1961, the bucket loader with the type designation “50 PS” was launched on the market. Under the hood operated the Deutz four-cylinder diesel engine F4L 712 with 60 hp, the all-wheel drive gave the loader power and maneuverability. The bucket capacity was 0.6 to 0.9 cubic meters.

The Kramer KS 510 bucket loader from 1964 had a gross vehicle weight of five tons, all-wheel drive and a bucket capacity of 0.7 to 0.9 tons. The load capacity was 1.8 tons. The machine was powered by the air-cooled Deutz F4L 812 diesel engine with 52 to 60 hp.

The Kramer shovel loader type KS 511 with all-wheel drive also had the 52 to 60 hp Deutz F4L 812 diesel engine under the hood. The photo from around 1965 shows it loading a Henschel all-wheel-drive tipper HS 12 HAK.

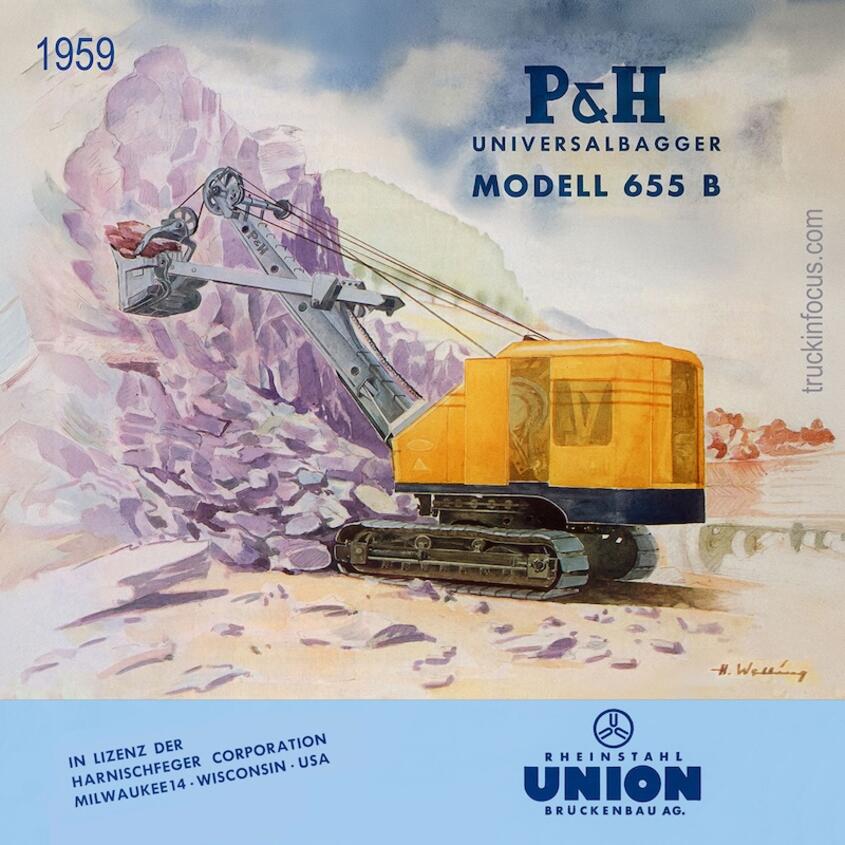

Rheinstahl Union Brückenbau AG, Dortmund

In 1965, Rheinstahl Union Brückenbau AG from Dortmund offered the new crawler excavator model 320. The 0.7 cubic meter crawler excavator was built under license from the US American P&H Harnischfeger Corporation from Wisconsin, Milwaukee. Its air-cooled diesel engine produced 88 hp. Rheinstahl Union Brückenbau AG became famous for structures such as the Aswan Dam in Egypt and the Zoo Bridge in Cologne. At the end of the 1960s, however, the company came under financial pressure and was taken over by Thyssen in 1973. The name Rheinstahl was abandoned in 1976.

This artistically designed brochure illustration from around 1961 shows the Rheinstahl Union crawler excavator type 655 B (license P&H). The excavator weighed 35.7 tons and could be used as a high or low bucket, dragline bucket and grab excavator and also as a pile driver or crane. The brochure states that the 655 B model had proven itself all over the world.

This brochure illustration also dates from the early sixties. It depicts the Rheinstahl Union crawler excavator type 955 A (license P&H). The 53.2-ton colossus had a digging vessel with a capacity of up to 2.5 cubic meters. It was only surpassed by the 65.7-ton type 1055 with a digging vessel capacity of up to 3.2 cubic meters, of which we unfortunately have no picture.

Stolmabau GmbH, Stolberg

Stolberger Maschinen- und Apparatebau GmbH in Stolberg near Aachen was little known, although it was the creator of some unusual construction machinery. Under the name Stolmabau, for example, it offered the Robuster RL II three-wheel bucket loader in the mid-sixties. Powered by the air-cooled two-cylinder Deutz F2L 812 diesel engine with 26 hp, the asymmetrically designed, almost five-metre-long machine with a closed cab and boom positioned to the right was agile, but not particularly powerful. Production of the loaders, which were also used in mining, ended in 1969.

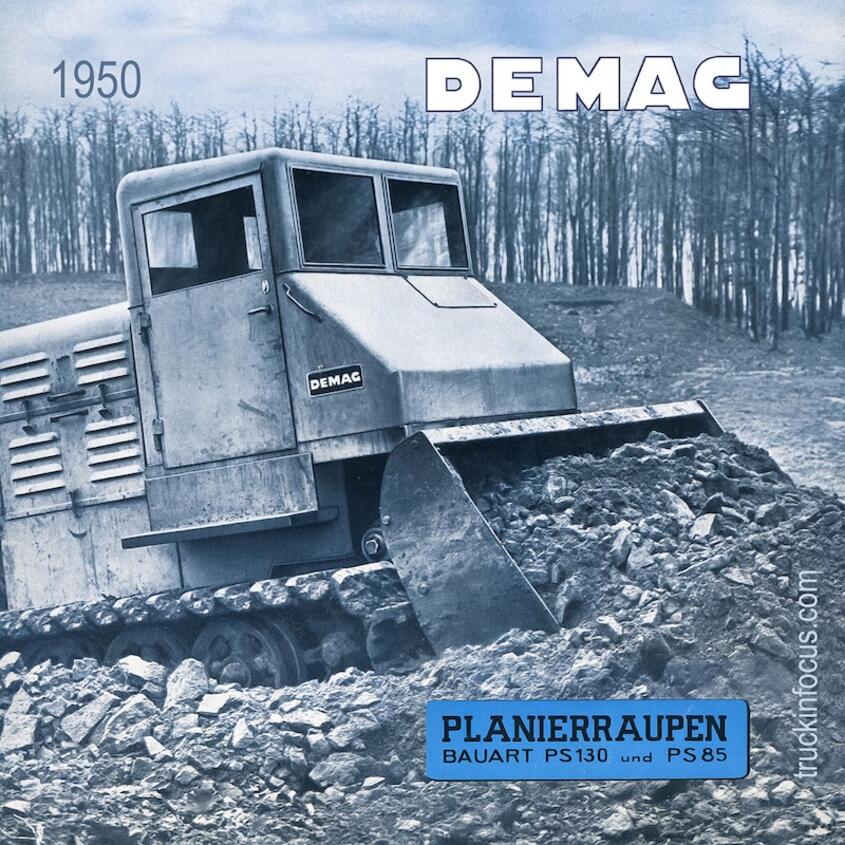

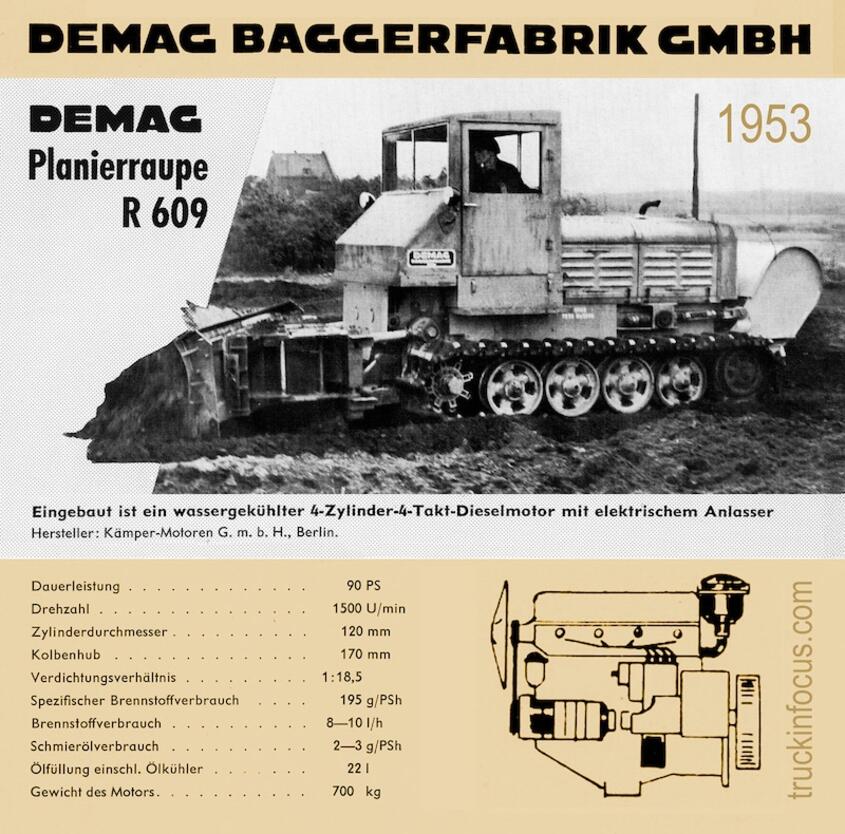

Deutsche Maschinenbau-Aktiengesellschaft (Demag), Duisburg

Demag (Deutsche Maschinenbau-Aktiengesellschaft) was founded in 1910 through the merger of various mechanical engineering companies. The company was initially successful in crane construction, but also produced railroad wagons and locomotives, cable excavators from 1925 and heavy armored vehicles during the Second World War. The first fully hydraulic excavator was produced in 1954, after bulldozers were also produced from around 1951, but their sales figures fell short of expectations and they were withdrawn from the line after just under ten years. The brochure cover shows the Demag bulldozer with a closed cab and the engine positioned behind it. The type PS 130 was powered by the Modag two-stroke RB 54 with 140 hp or optionally by the Kämper 6 D 13 engine with 150 hp. The shorter PS 85 model was powered by the Kämper 4 D 12 engine with 85 hp.

This Demag brochure from 1953 shows the R 609 bulldozer with a 90 hp Kämper engine. The weight of the crawler including dozer and winch was twelve tons, the maximum speed in fourth gear was 12.7 kilometers per hour.

The MAN F8 from 1953 will probably not have been available very often as a dump truck. Perhaps the vehicle in this MAN press photo is a prototype that did not go into series production or it was intended for export. The only thing that is certain is that the cable excavator just opening its claws above the tipper body is a Demag, presumably of the B 310 type.

Gebrüder Eicher Traktorenfabrik GmbH, Forstern

Eicher Traktoren- Geräteträger- und Zugmaschinenfabrik from Forstern in Upper Bavaria, founded in 1936, also offered construction machinery. The photo shows the 40 hp King Tiger wheeled tractor, which was also offered as a 65 hp Mammoth. The all-wheel tractors were powered by air-cooled Eicher diesel engines. The construction machines were equipped with a loading shovel and bucket excavator arm at the rear. After decades of decline with two bankruptcies and changing shareholders, tractor production finally came to an end in 2009. Only in India are trucks with the Eicher name still produced today.

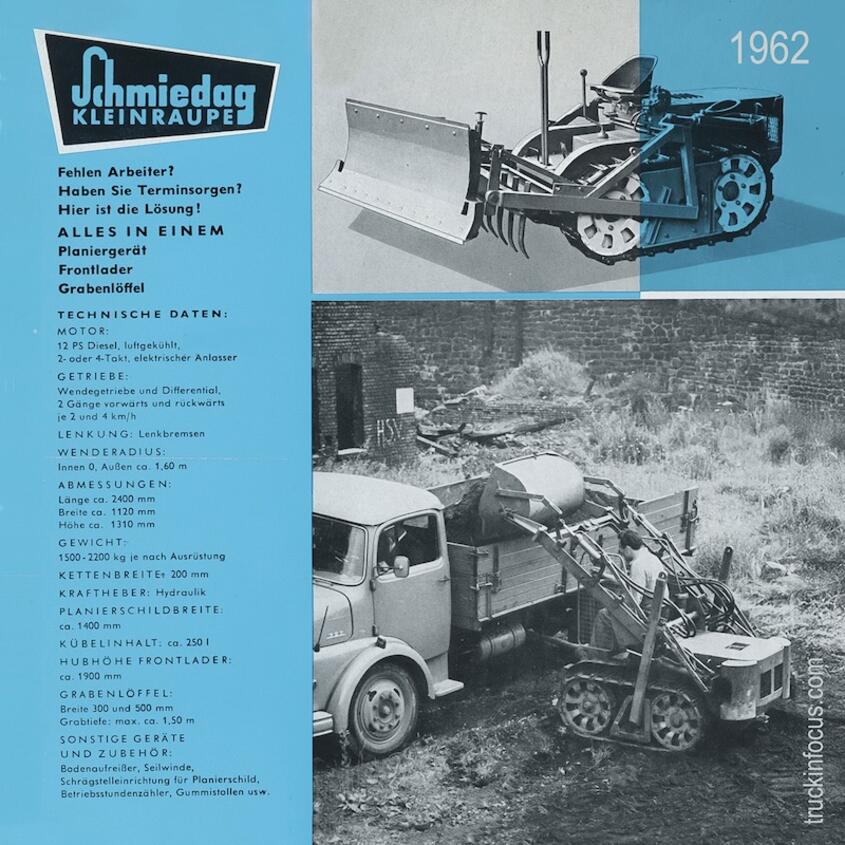

Schmiedag AG, Hagen

Another manufacturer of construction machinery was Schmiedag AG in Hagen. Founded in 1928, the mechanical engineering company produced components for motor vehicles, mining, railroads, agricultural machinery and tractors. In 1950, the Hansa, a single-axle, hand-guided 12 hp tractor, was launched on the market. From 1954 to 1967, small crawler tractors were also part of the line. The picture shows a brochure from 1962 advertising the Schmiedag small crawler tractor.

Mafi-Mulag

The Mafi-Mulag AS-500 shovel loader appeared in 1966. Unfortunately, searches on the Internet yielded no results for this machine. Some technical data was found on the back of the original factory photo, which can be seen here: bucket capacity 500 liters, one ton payload, all-wheel drive, motorization by air-cooled Güldner two-cylinder engine with 26 hp and with hydrostatic drive, also from Güldner.

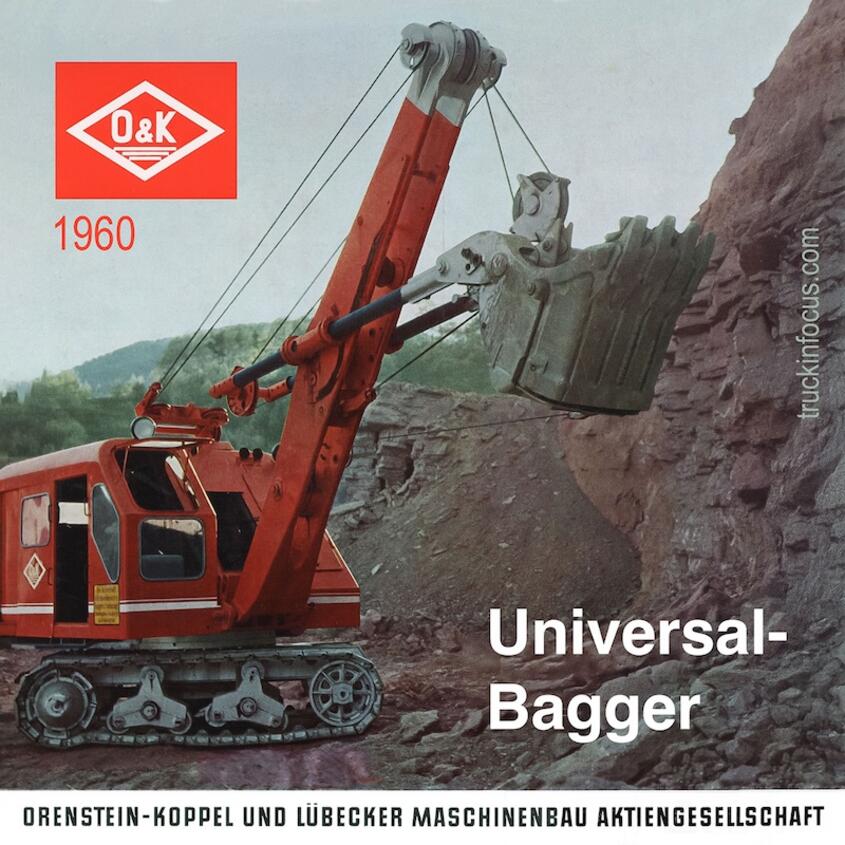

Orenstein & Koppel AG (O&K), Berlin

Orenstein & Koppel (abbreviated to O&K) was a German engineering company founded in Berlin-Schlachtensee in 1876 and transformed into a public limited company in 1897. O&K initially supplied field railway accessories such as trolleys, tracks and points and later manufactured a wide range of construction machinery, mainly excavators in various designs, but also road graders, tippers and mobile cranes, in addition to locomotives and wagons for freight and passenger transport. One of the smallest O&K machines was the three-wheeled Motrak AS 030 dumper with a 300 or 400-liter tipper body and an air-cooled ILO single-cylinder engine with 5.4 hp. The “driver” of the bizarre implement could steer effortlessly, but had to walk along.

The O&K dumper Motrak AS 150 was two sizes larger, designed as a three-way tipper with a hydraulically operated 0.85 to 1.50 cubic meter skip. The air-cooled Porenstein & Koppel two-stroke diesel of type 113 R1 DL produced 16 hp

The O&K dumper AS 610 with fixed cab and four to five cubic meter tipper body was almost a full-grown dump truck. The air-cooled Deutz F6L 514 diesel engine produced an impressive 90 hp.

The three-axle Orensten & Koppel EH 361 earth planer with double-axle drive was also equipped with a Deutz diesel engine, the four-cylinder F4l 514 with 65 hp. In the photo, the earth grader is spreading coarse gravel with its front blade.

Orenstein & Koppel-Mobilbagger vom Typ LS 041 mit Allradantrieb, ausgerüstet als Kran, bei der Unterbringung von Eisenrohren in einem Materiallager. Das Foto ist mit 1962 datiert.

Orenstein & Koppel brochure design from 1960 - the inside pages describe the O&K universal excavator in the versions with high and low bucket, as a grab excavator and with dragline bucket. There were different types with bucket capacities from 280 to 1750 liters, whereby the types up to 700 liters could also be supplied for mounting on truck chassis.

Eduard Linnhoff AG, Berlin and Northeim

Maschinenfabrik Eduard Linnhoff from Berlin-Tempelhof was founded in 1925. From 1955, the company had a second site in Northeim near Göttingen on a plot of land that it had rented five years earlier. Linnhoff did not leave many traces behind after filing for bankruptcy in 1970. There is almost nothing about Linnhoff on the Internet, although Linhoff construction machinery once played an important role in the industry. The photo shows a stationary, fully automatic blacktop mixing and production plant called the Linnhoff Kompaktomat. The machine is loading an L 312 Mercedes truck.

So-called tar boilers were a common sight on road construction sites in the fifties and sixties. This picture shows a Linnhoff special trailer with the difficult-to-understand name Automain, which functioned as a self-propelled tar boiling and pump spraying system for 750 to 1150 liters. This device could process up to ten tons of bitumen in eight to ten hours. The photo was taken around 1960.

The somewhat more modern version of a trailer built as a tar boiler was the Linnhoff special trailer with a special body as a 1.8 cubic meter tar heater with oil firing and its own drive. Its capacity was four tons of bitumen. The photo from the early sixties shows the device as delivered.

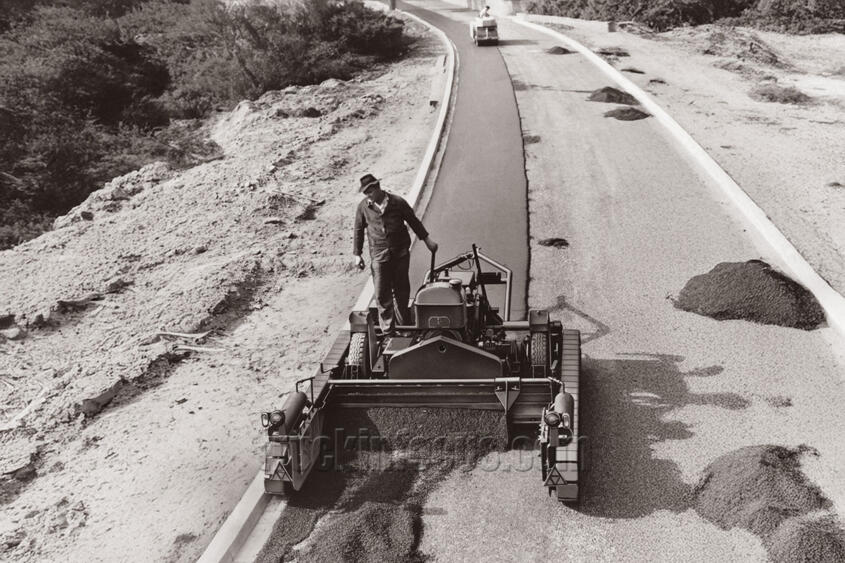

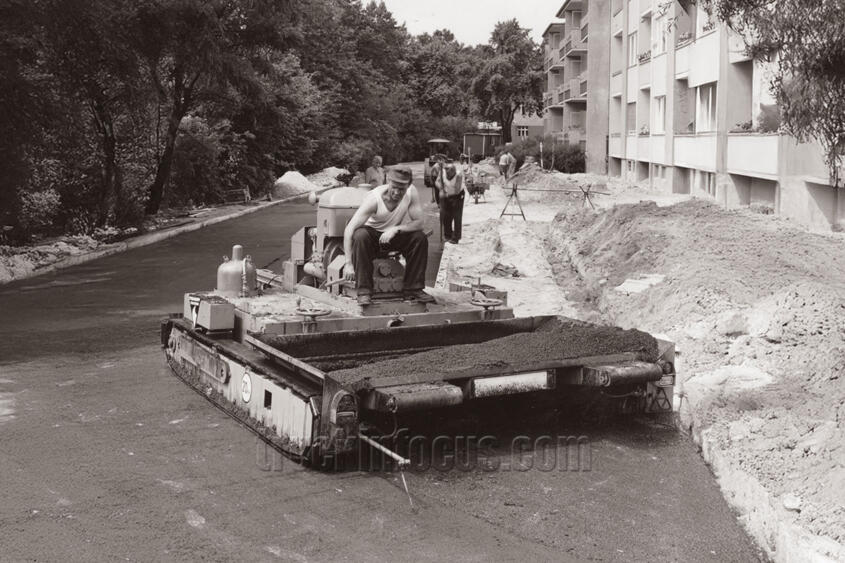

Road pavers were another specialty of Maschinenfabrik Eduard Linnhoff. These two photos from around 1962 show the self-propelled Linnhoff blacktop paver for a working width of 0.5 to 2.04 meters. The machine could process up to 30 tons of material per hour.

This photo also dates from around 1962 and shows a road paver for a working width of between half a meter and three meters. Up to 60 tons of material could be processed per hour.

Der selbstfahrende Linnhoff-Schwarzdeckenfertiger für eine Arbeitsbreite von 2,2 bis 4,5 Metern konnte bis zu 100 Tonnen Material pro Stunde verarbeiten. Das Foto aus den frühen Sechziger Jahren zeigt eine Baustelle auf der Berliner AVUS, der heutigen Autobahn A 115. Die 1921 eröffnete Automobilverkehrs- und Übungsstrecke galt als erste ausschließlich dem Kraftfahrzeugverkehr vorbehaltene Straße der Welt.

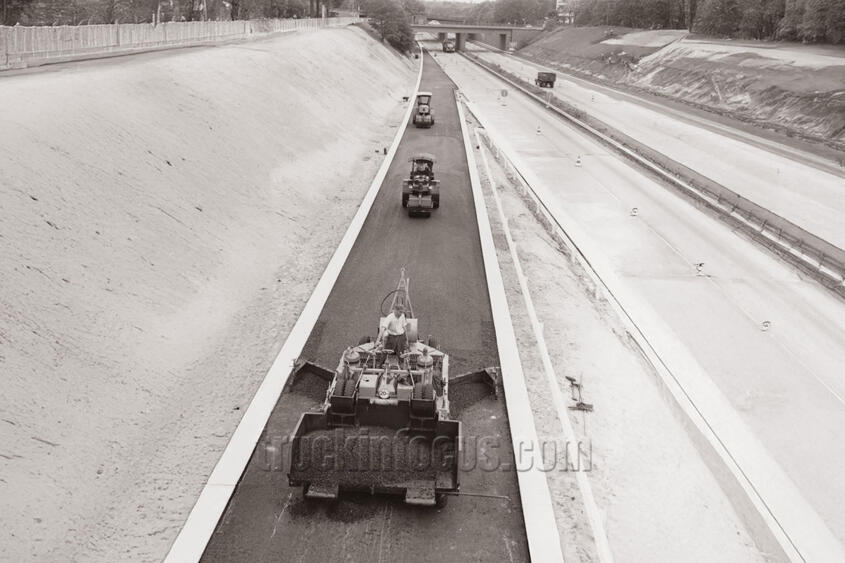

These two Linnhoff blacktop pavers are also the model with a working width of 2.2 to 4.5 meters. The photo was taken around 1962 at the Kamen interchange.

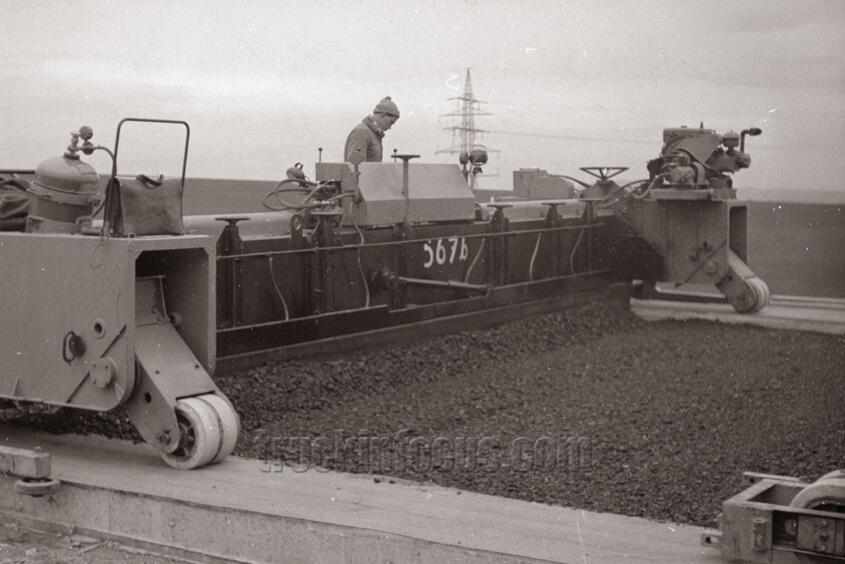

The Linnhoff blacktop paver in the Autobahn version was designed for working widths of 3 to 9.5 meters. The working speed could be varied between 0.2 and 3.0 meters per minute, while the transport speed was 15 meters per minute.

The Linhoff Super 600 road paver was launched in 1965. The photo shows it paving a binder course. Its paving capacity was 250 tons per hour.

Joseph Vögele AG, Ludwigshafen

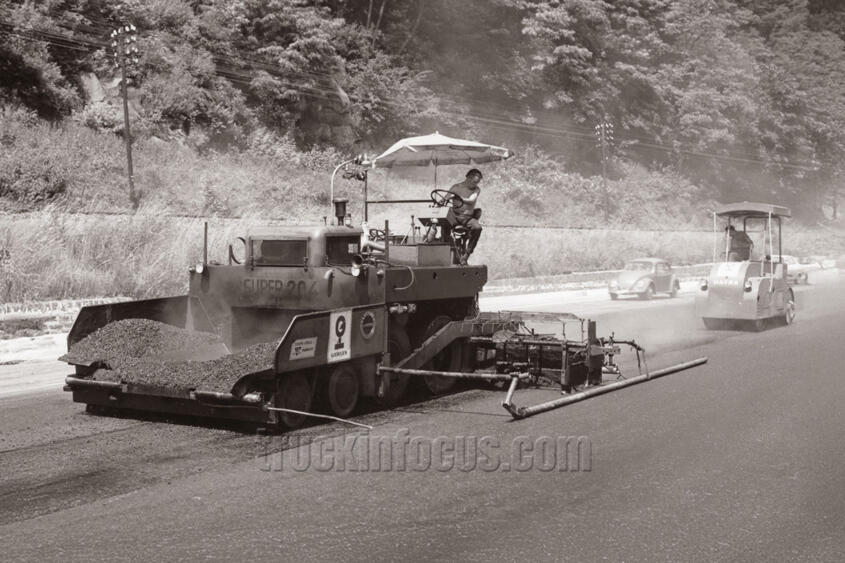

Joseph Vögele AG from Ludwigshafen is now the world market leader in road pavers, as can be read on the company's website. As part of the Wirtgen Group, the company belongs to the American agricultural and construction machinery group Deere & Company. The history: After being founded in 1836, the company initially established itself as a supplier for the railroad and had turnouts and shunting systems in its production program. After 1925, Vögele began to produce road construction machines, and the first concrete paving trains, soil mortars and asphalt pavers were built. The two photos from 1969 show the Vögele Super 204 four-axle blacktop paver with pneumatic tires. The machine was powered by the air-cooled Deutz F6L 912 diesel engine with 75 hp.

This article has been carefully compiled to the best of our knowledge. The information contained in the texts comes from the captions on the back of the photos, from advertising brochures of the respective companies and also from the Internet. Should any errors have crept in, please let us know. We recommend using the e-mail address corrections@truckinfocus.com

Some links from which we have obtained information:

https://verlagkraftakt.de/Krupp-des-Ostens-Das-Fahrzeugwerk-Hunger-aus-Frankenberg